INDUSTRIAL OVEN MANUFACTURER

Industrial oven design & Manufacturing

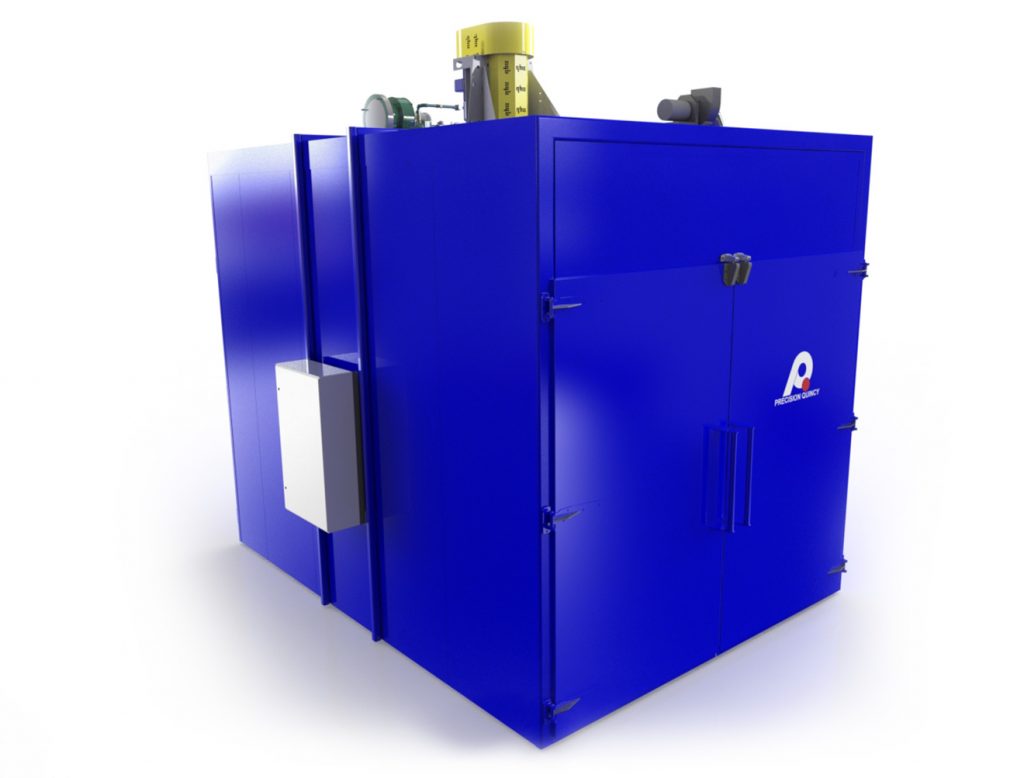

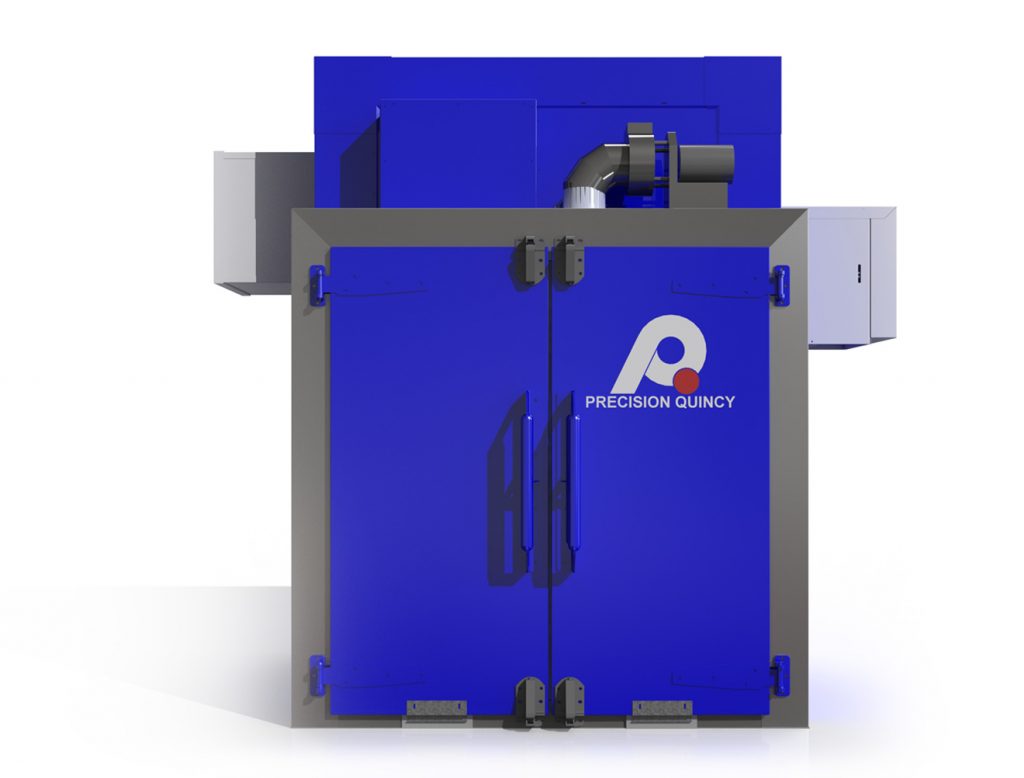

Precision Quincy sells industrial ovens with a “perfect fit.” We are proud of our 70-year legacy and the “Precision Quincy” name that we attach to every industrial oven design that leaves our facility in South Beloit, Illinois.

We take a modern approach to the design and manufacturing of industrial ovens and furnaces.

The summary below describes Precision Quincy’s industrial ovens and includes factors that you should consider in your buying decision. See also, Oven Primer: An Introduction to Industrial Process Ovens.

Whether electric or gas-fired, our industrial batch process ovens are good for thermal processing applications where the size of the load, or the product volume, varies.

Precision Quincy drum heating ovens are designed for high efficiency barrel warming up to 200F.

Our powder coating ovens — PCO model line — provides excellent powder coating oven performance in a small footprint package.

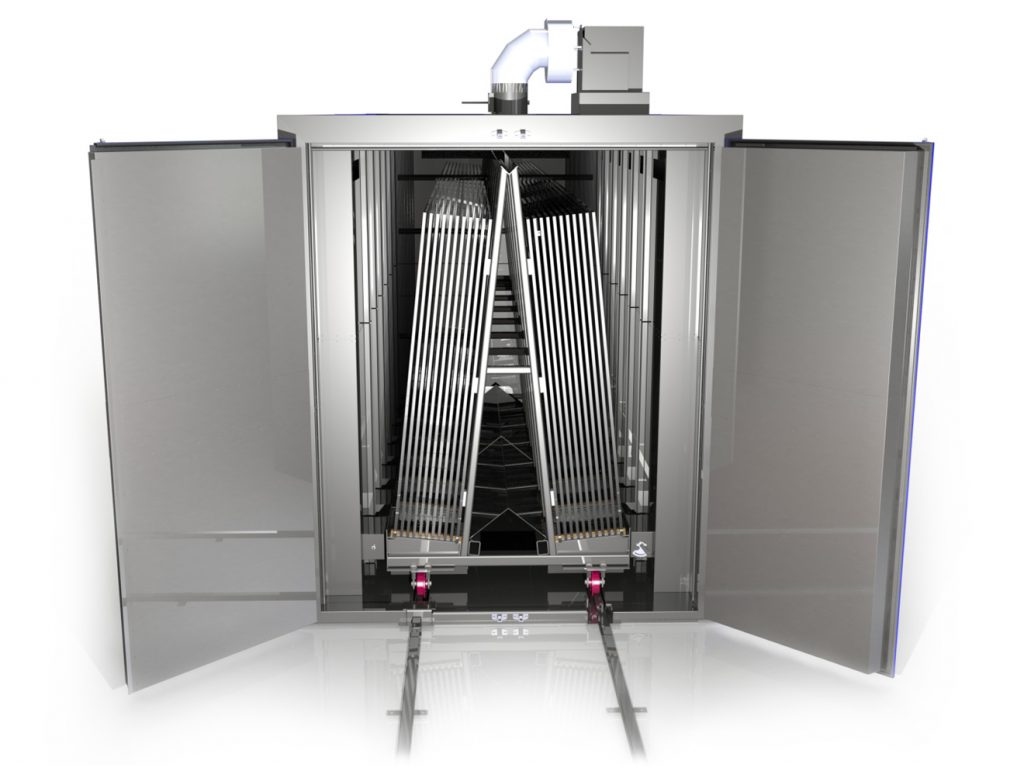

The TR Series walk in truck ovens can be purchased in 8 different sizes and in a variety of configurations for product loading as well as airflow options.

We provide custom conveyor ovens to meet your needs for a variety of heavy-duty and high volume applications. Contact our sales team to learn more.

Industrial walk in ovens (including truck-in ovens) can accommodate temperatures up to up to 1400⁰ F (760⁰ C), but most are usually less than 850⁰ F (454⁰ C).

Our industrial batch furnaces are available in 10 different standard sizes and customizable for your product loading with multiple air configuration options.

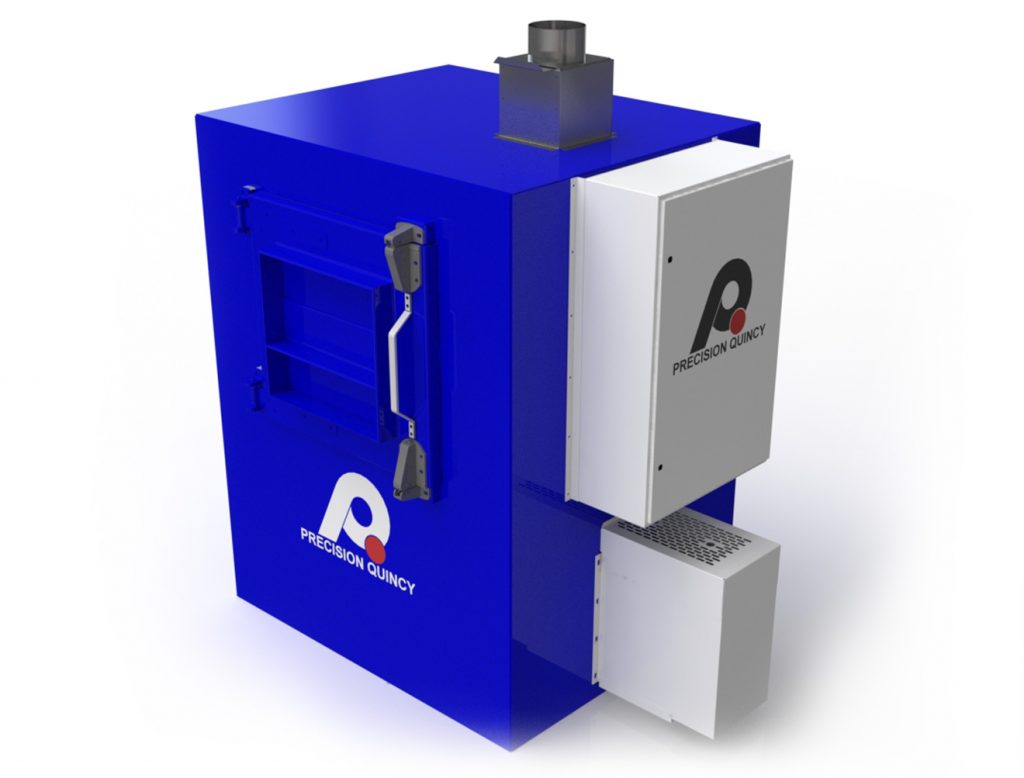

Lab ovens are best for smaller parts where the product is usually loaded by hand. They really shine when it comes to efficiency.

Industrial cabinet ovens are best for smaller parts where the product is usually loaded by hand. They really shine when it comes to efficiency.

These ovens are well suited to handle Glass Heat Soaking processes requiring a 650f maximum operating temperature.

WHAT IS AN INDUSTRIAL OVEN?

Precision Quincy Industrial Oven in a Factory

Precision Quincy Industrial Oven in a Factory

Industrial ovens are insulated enclosures or tunnels that operate at temperatures from slightly above ambient to 250°F (676°C) and are used for a variety of industrial applications, including curing, drying, powder coating, and for baking components, parts or final products.

Applications of industrial ovens are both large and small. In general, oven loading configurations take two essential forms, batch or continuous (conveyor line).

The most common sources of heat being used are electricity, gas (natural or propane), steam, hot water, and fuel oil. Forced convection is used when heated air needs to be introduced into the work area.

What are the applications of Industrial Ovens?

Applications of industrial ovens include:

- Aluminum Aging

- Annealing

- Burnoff

- Composites

- Curing/Baking

- Drying

- Finishing

- Glass Heat Soaking

- Heat Treating

- Hydrogen De-Embrittlement

- Post Curing

- Powder Coating

- Preheating

- Sintering

- Solution Heat Treating

- Stress Relieving

- Teflon Coating

- Tempering

Learn more about applications for industrial ovens.

The Difference Between Batch Ovens and Conveyor Ovens

Industrial ovens are generally divided into two categories, batch ovens and industrial conveyor ovens:

- Batch Ovens — Industrial batch ovens are appropriate when the application has inconsistent load sizes and production volumes.

- Conveyor Ovens (also called “Continuous Ovens”) — Industrial conveyor ovens are appropriate for processing high volume, low product-mix.

Precision Quincy designs, manufactures, and sells custom conveyor ovens through our brand Infratrol.

Oven Chamber Sizes

Industrial batch ovens are also identified by their chamber size:

Laboratory Ovens or Benchtop Ovens – A small industrial oven (less than 10 ft³), usually an electric oven used in laboratory, testing, or low production environments.

Cabinet Ovens – A small to medium (less than 100 ft³) electric or gas fired industrial oven with product shelves used in lower production manufacturing.

Walk-In Ovens and Truck-In Ovens – A medium to large (greater than 100 ft³) electric or gas fired industrial oven with product shelves or carts used in various manufacturing facilities.

Find out which ovens would best suit your industry.

OVEN DESIGN USING 3D MODELING

We live in a 3D world and our Precision Quincy engineers use 3D modeling tools that allow all of us to visualize commercial ovens in the same way. These tools not only improve the industrial oven design process, but also facilitate communication between our engineers and customers. Utilizing modern oven design methods results in industrial ovens with a “perfect fit,” which is especially critical for high-temperature commercial ovens and furnaces.

HIGH TEMPERATURE INDUSTRIAL OVENS

As the temperature inside a commercial oven rises above 600⁰ F (315⁰C), the steel used to construct the commercial oven responds with significant thermal expansion from heat. Unlike other industrial oven manufacturers, Precision Quincy designs an industrial oven and industrial furnace with multiple fixed pieces that fit together in a manner that relieves stress as thermal expansion occurs.

In other words, our commercial ovens “grow” to accommodate thermal expansion caused by heat resulting in an industrial oven or furnace with “zero” stress. For this reason, Precision Quincy ovens and furnaces are well suited for high temperatures up to 1400⁰ F (760⁰C).

TEMPERATURE UNIFORMITY

Our industrial oven designs result in superior heat and temperature uniformity. Many different factors influence temperature uniformity in a commercial oven, including controller calibration, sensor calibration, sensor placement within the work area, oven temperature (high temperature/greater variable), circulation (the greater the air circulation/the better the uniformity); placement of workload within the work area, airflow pattern, heat loss through walls, and metal-to-metal conduction.

At Precision Quincy Ovens, we take all of these variables into consideration and utilize a proven 10-point thermocouple test process to ensure the specified uniformity is obtained for the stated oven application or process. In addition, we supply each of our industrial ovens with a controller (or programmer) with the proper amount of control sensitivity, which will react accordingly to temperature fluctuations.

UNDERSTANDING OVEN CYCLE DYNAMICS

Our engineers will assist you in evaluating your products and processes to determine the appropriate industrial oven cycle dynamics, including proper oven capacity, set point temperature, ramp/soak profile, and cool down (if required). See Understanding Oven Cycle Dynamics.

OTHER INDUSTRIAL OVEN SERVICES

Precision Quincy is not only a commercial industrial oven supplier. We also offer a full range of industrial oven replacement parts and oven repair and maintenance services, including oven rebuilds and retrofits on all brands of commercial ovens for industrial use.

For more information on any of our commercial oven services or products, including oven design, sales, and installation, or if you still have questions about the type of industrial oven or furnace you need, please call Precision Quincy at (302) 602-8738 or request a quote.

Contact our sales and engineering professionals to clarify your requirements, get your questions answered, and learn about our oven solutions! Just send us a message or call 302-602-8738.

View All Industrial Oven Series and Models

| Model | Series | Interior Width | Interior Depth | Interior Height | Exterior Width | Exterior Depth | Max Temp (F) | Capacity (ft³) |

|---|---|---|---|---|---|---|---|---|

| 40A-350 | 40 | 36 | 36 | 36 | 60 | 44 | 350 | 27 |

| 40A-550 | 40 | 36 | 36 | 36 | 64 | 46 | 550 | 27 |

| 40B-350 | 40 | 48 | 30 | 48 | 75 | 37 | 350 | 40 |

| 40B-550 | 40 | 48 | 30 | 48 | 79 | 39 | 550 | 40 |

| 40C-350 | 40 | 48 | 48 | 38 | 75 | 55 | 350 | 51 |

| 40C-550 | 40 | 48 | 48 | 38 | 79 | 57 | 550 | 51 |

| 40D-350 | 40 | 55 | 30 | 60 | 80 | 36 | 350 | 57 |

| 40D-550 | 40 | 55 | 30 | 60 | 85 | 42 | 550 | 57 |

| 43A-350 | 43 | 36 | 36 | 36 | 60 | 44 | 350 | 27 |

| 43A-550 | 43 | 36 | 36 | 36 | 64 | 46 | 550 | 27 |

| 43B-350 | 43 | 48 | 30 | 48 | 75 | 37 | 350 | 40 |

| 43B-550 | 43 | 48 | 30 | 48 | 79 | 39 | 550 | 40 |

| 43C-350 | 43 | 48 | 48 | 38 | 75 | 55 | 350 | 51 |

| 43C-550 | 43 | 48 | 48 | 38 | 79 | 57 | 550 | 51 |

| 43D-350 | 43 | 55 | 30 | 60 | 80 | 36 | 350 | 57 |

| 43D-550 | 43 | 55 | 30 | 60 | 85 | 42 | 550 | 57 |

| SP2S-16 | SP2S | 76 | 51 | 48 | 233 | 95 | 200 | 430.66 |

| HD5B-404-6 | HD5B | 48 | 48 | 72 | 82 | 113 | 650 | 96 |

| HD5B-404-7 | HD5B | 48 | 48 | 84 | 82 | 113 | 650 | 112 |

| HD5B-404-8 | HD5B | 48 | 48 | 96 | 82 | 113 | 650 | 128 |

| HD5B-406-6 | HD5B | 48 | 72 | 72 | 82 | 137 | 650 | 144 |

| HD5B-406-7 | HD5B | 48 | 72 | 84 | 82 | 137 | 650 | 168 |

| HD5B-406-8 | HD5B | 48 | 72 | 96 | 82 | 137 | 650 | 192 |

| HD5B-408-6 | HD5B | 48 | 96 | 72 | 82 | 161 | 650 | 192 |

| HD5B-408-7 | HD5B | 48 | 96 | 84 | 82 | 165 | 650 | 224 |

| HD5B-408-8 | HD5B | 48 | 96 | 96 | 86 | 165 | 650 | 256 |

| HD5B-410-6 | HD5B | 48 | 120 | 72 | 86 | 189 | 650 | 240 |

| HD5B-410-7 | HD5B | 48 | 120 | 84 | 86 | 189 | 650 | 280 |

| HD5B-410-8 | HD5B | 48 | 120 | 96 | 86 | 189 | 650 | 320 |

| HD5B-412-6 | HD5B | 48 | 144 | 72 | 86 | 213 | 650 | 288 |

| HD5B-412-7 | HD5B | 48 | 144 | 84 | 86 | 213 | 650 | 336 |

| HD5B-412-8 | HD5B | 48 | 144 | 96 | 90 | 213 | 650 | 384 |

| HD5B-414-6 | HD5B | 48 | 168 | 72 | 86 | 237 | 650 | 336 |

| HD5B-414-7 | HD5B | 48 | 168 | 84 | 90 | 237 | 650 | 392 |

| HD5B-414-8 | HD5B | 48 | 168 | 96 | 86 | 237 | 650 | 448 |

| HD5B-416-6 | HD5B | 48 | 192 | 72 | 90 | 261 | 650 | 384 |

| HD5B-416-7 | HD5B | 48 | 192 | 84 | 86 | 261 | 650 | 448 |

| HD5B-416-8 | HD5B | 48 | 192 | 96 | 90 | 265 | 650 | 512 |

| HD5B-504-6 | HD5B | 60 | 48 | 72 | 94 | 113 | 650 | 120 |

| HD5B-504-7 | HD5B | 60 | 48 | 84 | 94 | 113 | 650 | 140 |

| HD5B-504-8 | HD5B | 60 | 48 | 96 | 94 | 113 | 650 | 160 |

| HD5B-506-6 | HD5B | 60 | 72 | 72 | 94 | 137 | 650 | 180 |

| HD5B-506-7 | HD5B | 60 | 72 | 84 | 94 | 137 | 650 | 210 |

| HD5B-506-8 | HD5B | 60 | 72 | 96 | 98 | 141 | 650 | 240 |

| HD5B-508-6 | HD5B | 60 | 96 | 72 | 98 | 165 | 650 | 240 |

| HD5B-508-7 | HD5B | 60 | 96 | 84 | 98 | 165 | 650 | 280 |

| HD5B-508-8 | HD5B | 60 | 96 | 96 | 98 | 165 | 650 | 320 |

| HD5B-510-6 | HD5B | 60 | 120 | 72 | 98 | 189 | 650 | 300 |

| HD5B-510-7 | HD5B | 60 | 120 | 84 | 98 | 189 | 650 | 350 |

| HD5B-510-8 | HD5B | 60 | 120 | 96 | 102 | 189 | 650 | 400 |

| HD5B-512-6 | HD5B | 60 | 144 | 72 | 98 | 213 | 650 | 360 |

| HD5B-512-7 | HD5B | 60 | 144 | 84 | 98 | 213 | 650 | 420 |

| HD5B-512-8 | HD5B | 60 | 144 | 96 | 98 | 213 | 650 | 480 |

| HD5B-514-6 | HD5B | 60 | 168 | 72 | 98 | 237 | 650 | 420 |

| HD5B-514-7 | HD5B | 60 | 168 | 84 | 102 | 237 | 650 | 490 |

| HD5B-514-8 | HD5B | 60 | 168 | 96 | 102 | 241 | 650 | 560 |

| HD5B-516-6 | HD5B | 60 | 192 | 72 | 98 | 261 | 650 | 480 |

| HD5B-516-7 | HD5B | 60 | 192 | 84 | 102 | 265 | 650 | 560 |

| HD5B-516-8 | HD5B | 60 | 192 | 96 | 102 | 265 | 650 | 640 |

| HD5B-604-6 | HD5B | 72 | 48 | 72 | 106 | 113 | 650 | 144 |

| HD5B-604-7 | HD5B | 72 | 48 | 84 | 106 | 113 | 650 | 168 |

| HD5B-604-8 | HD5B | 72 | 48 | 96 | 106 | 113 | 650 | 192 |

| HD5B-606-6 | HD5B | 72 | 72 | 72 | 106 | 137 | 650 | 216 |

| HD5B-606-7 | HD5B | 72 | 72 | 84 | 110 | 141 | 650 | 252 |

| HD5B-606-8 | HD5B | 72 | 72 | 96 | 110 | 141 | 650 | 288 |

| HD5B-608-6 | HD5B | 72 | 96 | 72 | 110 | 165 | 650 | 288 |

| HD5B-608-7 | HD5B | 72 | 96 | 84 | 110 | 165 | 650 | 336 |

| HD5B-608-8 | HD5B | 72 | 96 | 96 | 114 | 165 | 650 | 384 |

| HD5B-610-6 | HD5B | 72 | 120 | 72 | 110 | 189 | 650 | 360 |

| HD5B-610-7 | HD5B | 72 | 120 | 84 | 110 | 189 | 650 | 420 |

| HD5B-610-8 | HD5B | 72 | 120 | 96 | 110 | 189 | 650 | 480 |

| HD5B-612-6 | HD5B | 72 | 144 | 72 | 110 | 213 | 650 | 432 |

| HD5B-612-7 | HD5B | 72 | 144 | 84 | 114 | 217 | 650 | 504 |

| HD5B-612-8 | HD5B | 72 | 144 | 96 | 114 | 217 | 650 | 576 |

| HD5B-614-6 | HD5B | 72 | 168 | 72 | 114 | 241 | 650 | 504 |

| HD5B-614-7 | HD5B | 72 | 168 | 84 | 114 | 241 | 650 | 588 |

| HD5B-614-8 | HD5B | 72 | 168 | 96 | 114 | 264 | 650 | 672 |

| HD5B-616-6 | HD5B | 72 | 192 | 72 | 114 | 265 | 650 | 576 |

| HD5B-616-7 | HD5B | 72 | 192 | 84 | 114 | 288 | 650 | 672 |

| HD5B-616-8 | HD5B | 72 | 192 | 96 | 114 | 288 | 650 | 768 |

| HD5B-704-6 | HD5B | 84 | 48 | 72 | 118 | 113 | 650 | 168 |

| HD5B-704-7 | HD5B | 84 | 48 | 84 | 118 | 113 | 650 | 196 |

| HD5B-704-8 | HD5B | 84 | 48 | 96 | 118 | 117 | 650 | 224 |

| HD5B-706-6 | HD5B | 84 | 72 | 72 | 122 | 141 | 650 | 252 |

| HD5B-706-7 | HD5B | 84 | 72 | 84 | 122 | 141 | 650 | 294 |

| HD5B-706-8 | HD5B | 84 | 72 | 96 | 122 | 141 | 650 | 336 |

| HD5B-708-6 | HD5B | 84 | 96 | 72 | 122 | 165 | 650 | 336 |

| HD5B-708-7 | HD5B | 84 | 96 | 84 | 126 | 165 | 650 | 392 |

| HD5B-708-8 | HD5B | 84 | 96 | 96 | 122 | 165 | 650 | 448 |

| HD5B-710-6 | HD5B | 84 | 120 | 72 | 122 | 189 | 650 | 420 |

| HD5B-710-7 | HD5B | 84 | 120 | 84 | 126 | 189 | 650 | 490 |

| HD5B-710-8 | HD5B | 84 | 120 | 96 | 126 | 193 | 650 | 560 |

| HD5B-712-6 | HD5B | 84 | 144 | 72 | 126 | 217 | 650 | 504 |

| HD5B-712-7 | HD5B | 84 | 144 | 84 | 122 | 217 | 650 | 588 |

| HD5B-712-8 | HD5B | 84 | 144 | 96 | 126 | 240 | 650 | 672 |

| HD5B-714-6 | HD5B | 84 | 168 | 72 | 126 | 241 | 650 | 588 |

| HD5B-714-7 | HD5B | 84 | 168 | 84 | 126 | 264 | 650 | 686 |

| HD5B-714-8 | HD5B | 84 | 168 | 96 | 126 | 264 | 650 | 784 |

| HD5B-716-6 | HD5B | 84 | 192 | 72 | 126 | 288 | 650 | 672 |

| HD5B-716-7 | HD5B | 84 | 192 | 84 | 126 | 288 | 650 | 784 |

| HD5B-716-8 | HD5B | 84 | 192 | 96 | 130 | 288 | 650 | 896 |

| HD5B-804-6 | HD5B | 96 | 48 | 72 | 130 | 113 | 650 | 192 |

| HD5B-804-7 | HD5B | 96 | 48 | 84 | 130 | 117 | 650 | 224 |

| HD5B-804-8 | HD5B | 96 | 48 | 96 | 134 | 117 | 650 | 256 |

| HD5B-806-6 | HD5B | 96 | 72 | 72 | 134 | 141 | 650 | 288 |

| HD5B-806-7 | HD5B | 96 | 72 | 84 | 134 | 141 | 650 | 336 |

| HD5B-806-8 | HD5B | 96 | 72 | 96 | 138 | 141 | 650 | 384 |

| HD5B-808-6 | HD5B | 96 | 96 | 72 | 138 | 165 | 650 | 384 |

| HD5B-808-7 | HD5B | 96 | 96 | 84 | 134 | 165 | 650 | 448 |

| HD5B-808-8 | HD5B | 96 | 96 | 96 | 138 | 169 | 650 | 512 |

| HD5B-810-6 | HD5B | 96 | 120 | 72 | 134 | 189 | 650 | 480 |

| HD5B-810-7 | HD5B | 96 | 120 | 84 | 138 | 193 | 650 | 560 |

| HD5B-810-8 | HD5B | 96 | 120 | 96 | 138 | 193 | 650 | 640 |

| HD5B-812-6 | HD5B | 96 | 144 | 72 | 138 | 217 | 650 | 576 |

| HD5B-812-7 | HD5B | 96 | 144 | 84 | 138 | 240 | 650 | 672 |

| HD5B-812-8 | HD5B | 96 | 144 | 96 | 138 | 240 | 650 | 768 |

| HD5B-814-6 | HD5B | 96 | 168 | 72 | 138 | 264 | 650 | 672 |

| HD5B-814-7 | HD5B | 96 | 168 | 84 | 138 | 264 | 650 | 784 |

| HD5B-814-8 | HD5B | 96 | 168 | 96 | 142 | 264 | 650 | 896 |

| HD5B-816-6 | HD5B | 96 | 192 | 72 | 138 | 288 | 650 | 768 |

| HD5B-816-7 | HD5B | 96 | 192 | 84 | 142 | 288 | 650 | 896 |

| HD5B-816-8 | HD5B | 96 | 192 | 96 | 142 | 288 | 650 | 1024 |

| HD5T-404-6 | HD5T | 48 | 48 | 72 | 82 | 113 | 650 | 96 |

| HD5T-404-7 | HD5T | 48 | 48 | 84 | 82 | 113 | 650 | 112 |

| HD5T-404-8 | HD5T | 48 | 48 | 96 | 82 | 113 | 650 | 128 |

| HD5T-406-6 | HD5T | 48 | 72 | 72 | 82 | 137 | 650 | 144 |

| HD5T-406-7 | HD5T | 48 | 72 | 84 | 82 | 137 | 650 | 168 |

| HD5T-406-8 | HD5T | 48 | 72 | 96 | 82 | 137 | 650 | 192 |

| HD5T-408-6 | HD5T | 48 | 96 | 72 | 82 | 161 | 650 | 192 |

| HD5T-408-7 | HD5T | 48 | 96 | 84 | 82 | 165 | 650 | 224 |

| HD5T-408-8 | HD5T | 48 | 96 | 96 | 86 | 165 | 650 | 256 |

| HD5T-410-6 | HD5T | 48 | 120 | 72 | 86 | 189 | 650 | 240 |

| HD5T-410-7 | HD5T | 48 | 120 | 84 | 86 | 189 | 650 | 280 |

| HD5T-410-8 | HD5T | 48 | 120 | 96 | 86 | 189 | 650 | 320 |

| HD5T-412-6 | HD5T | 48 | 144 | 72 | 86 | 213 | 650 | 288 |

| HD5T-412-7 | HD5T | 48 | 144 | 84 | 86 | 213 | 650 | 336 |

| HD5T-412-8 | HD5T | 48 | 144 | 96 | 90 | 213 | 650 | 384 |

| HD5T-414-6 | HD5T | 48 | 168 | 72 | 86 | 237 | 650 | 336 |

| HD5T-414-7 | HD5T | 48 | 168 | 84 | 90 | 237 | 650 | 392 |

| HD5T-414-8 | HD5T | 48 | 168 | 96 | 86 | 237 | 650 | 448 |

| HD5T-416-6 | HD5T | 48 | 192 | 72 | 90 | 261 | 650 | 384 |

| HD5T-416-7 | HD5T | 48 | 192 | 84 | 86 | 261 | 650 | 448 |

| HD5T-416-8 | HD5T | 48 | 192 | 96 | 90 | 265 | 650 | 512 |

| HD5T-504-6 | HD5T | 60 | 48 | 72 | 94 | 113 | 650 | 120 |

| HD5T-504-7 | HD5T | 60 | 48 | 84 | 94 | 113 | 650 | 140 |

| HD5T-504-8 | HD5T | 60 | 48 | 96 | 94 | 113 | 650 | 160 |

| HD5T-506-6 | HD5T | 60 | 72 | 72 | 94 | 137 | 650 | 180 |

| HD5T-506-7 | HD5T | 60 | 72 | 84 | 94 | 137 | 650 | 210 |

| HD5T-506-8 | HD5T | 60 | 72 | 96 | 98 | 141 | 650 | 240 |

| HD5T-508-6 | HD5T | 60 | 96 | 72 | 98 | 165 | 650 | 240 |

| HD5T-508-7 | HD5T | 60 | 96 | 84 | 98 | 165 | 650 | 280 |

| HD5T-508-8 | HD5T | 60 | 96 | 96 | 98 | 165 | 650 | 320 |

| HD5T-510-6 | HD5T | 60 | 120 | 72 | 98 | 189 | 650 | 300 |

| HD5T-510-7 | HD5T | 60 | 120 | 84 | 98 | 189 | 650 | 350 |

| HD5T-510-8 | HD5T | 60 | 120 | 96 | 102 | 189 | 650 | 400 |

| HD5T-512-6 | HD5T | 60 | 144 | 72 | 98 | 213 | 650 | 360 |

| HD5T-512-7 | HD5T | 60 | 144 | 84 | 98 | 213 | 650 | 420 |

| HD5T-512-8 | HD5T | 60 | 144 | 96 | 98 | 213 | 650 | 480 |

| HD5T-514-6 | HD5T | 60 | 168 | 72 | 98 | 237 | 650 | 420 |

| HD5T-514-7 | HD5T | 60 | 168 | 84 | 102 | 237 | 650 | 490 |

| HD5T-514-8 | HD5T | 60 | 168 | 96 | 102 | 241 | 650 | 560 |

| HD5T-516-6 | HD5T | 60 | 192 | 72 | 98 | 261 | 650 | 480 |

| HD5T-516-7 | HD5T | 60 | 192 | 84 | 102 | 265 | 650 | 560 |

| HD5T-516-8 | HD5T | 60 | 192 | 96 | 102 | 265 | 650 | 640 |

| HD5T-604-6 | HD5T | 72 | 48 | 72 | 106 | 113 | 650 | 144 |

| HD5T-604-7 | HD5T | 72 | 48 | 84 | 106 | 113 | 650 | 168 |

| HD5T-604-8 | HD5T | 72 | 48 | 96 | 106 | 113 | 650 | 192 |

| HD5T-606-6 | HD5T | 72 | 72 | 72 | 106 | 137 | 650 | 216 |

| HD5T-606-7 | HD5T | 72 | 72 | 84 | 110 | 141 | 650 | 252 |

| HD5T-606-8 | HD5T | 72 | 72 | 96 | 110 | 141 | 650 | 288 |

| HD5T-608-6 | HD5T | 72 | 96 | 72 | 110 | 165 | 650 | 288 |

| HD5T-608-7 | HD5T | 72 | 96 | 84 | 110 | 165 | 650 | 336 |

| HD5T-608-8 | HD5T | 72 | 96 | 96 | 114 | 165 | 650 | 384 |

| HD5T-610-6 | HD5T | 72 | 120 | 72 | 110 | 189 | 650 | 360 |

| HD5T-610-7 | HD5T | 72 | 120 | 84 | 110 | 189 | 650 | 420 |

| HD5T-610-8 | HD5T | 72 | 120 | 96 | 110 | 189 | 650 | 480 |

| HD5T-612-6 | HD5T | 72 | 144 | 72 | 110 | 213 | 650 | 432 |

| HD5T-612-7 | HD5T | 72 | 144 | 84 | 114 | 217 | 650 | 504 |

| HD5T-612-8 | HD5T | 72 | 144 | 96 | 114 | 217 | 650 | 576 |

| HD5T-614-6 | HD5T | 72 | 168 | 72 | 114 | 241 | 650 | 504 |

| HD5T-614-7 | HD5T | 72 | 168 | 84 | 114 | 241 | 650 | 588 |

| HD5T-614-8 | HD5T | 72 | 168 | 96 | 114 | 264 | 650 | 672 |

| HD5T-616-6 | HD5T | 72 | 192 | 72 | 114 | 265 | 650 | 576 |

| HD5T-616-7 | HD5T | 72 | 192 | 84 | 114 | 288 | 650 | 672 |

| HD5T-616-8 | HD5T | 72 | 192 | 96 | 114 | 288 | 650 | 768 |

| HD5T-704-6 | HD5T | 84 | 48 | 72 | 118 | 113 | 650 | 168 |

| HD5T-704-7 | HD5T | 84 | 48 | 84 | 118 | 113 | 650 | 196 |

| HD5T-704-8 | HD5T | 84 | 48 | 96 | 118 | 117 | 650 | 224 |

| HD5T-706-6 | HD5T | 84 | 72 | 72 | 122 | 141 | 650 | 252 |

| HD5T-706-7 | HD5T | 84 | 72 | 84 | 122 | 141 | 650 | 294 |

| HD5T-706-8 | HD5T | 84 | 72 | 96 | 122 | 141 | 650 | 336 |

| HD5T-708-6 | HD5T | 84 | 96 | 72 | 122 | 165 | 650 | 336 |

| HD5T-708-7 | HD5T | 84 | 96 | 84 | 126 | 165 | 650 | 392 |

| HD5T-708-8 | HD5T | 84 | 96 | 96 | 122 | 165 | 650 | 448 |

| HD5T-710-6 | HD5T | 84 | 120 | 72 | 122 | 189 | 650 | 420 |

| HD5T-710-7 | HD5T | 84 | 120 | 84 | 126 | 189 | 650 | 490 |

| HD5T-710-8 | HD5T | 84 | 120 | 96 | 126 | 193 | 650 | 560 |

| HD5T-712-6 | HD5T | 84 | 144 | 72 | 126 | 217 | 650 | 504 |

| HD5T-712-7 | HD5T | 84 | 144 | 84 | 122 | 217 | 650 | 588 |

| HD5T-712-8 | HD5T | 84 | 144 | 96 | 126 | 240 | 650 | 672 |

| HD5T-714-6 | HD5T | 84 | 168 | 72 | 126 | 241 | 650 | 588 |

| HD5T-714-7 | HD5T | 84 | 168 | 84 | 126 | 264 | 650 | 686 |

| HD5T-714-8 | HD5T | 84 | 168 | 96 | 126 | 264 | 650 | 784 |

| HD5T-716-6 | HD5T | 84 | 192 | 72 | 126 | 288 | 650 | 672 |

| HD5T-716-7 | HD5T | 84 | 192 | 84 | 126 | 288 | 650 | 784 |

| HD5T-716-8 | HD5T | 84 | 192 | 96 | 130 | 288 | 650 | 896 |

| HD5T-804-6 | HD5T | 96 | 48 | 72 | 130 | 113 | 650 | 192 |

| HD5T-804-7 | HD5T | 96 | 48 | 84 | 130 | 117 | 650 | 224 |

| HD5T-804-8 | HD5T | 96 | 48 | 96 | 134 | 117 | 650 | 256 |

| HD5T-806-6 | HD5T | 96 | 72 | 72 | 134 | 141 | 650 | 288 |

| HD5T-806-7 | HD5T | 96 | 72 | 84 | 134 | 141 | 650 | 336 |

| HD5T-806-8 | HD5T | 96 | 72 | 96 | 138 | 141 | 650 | 384 |

| HD5T-808-6 | HD5T | 96 | 96 | 72 | 138 | 165 | 650 | 384 |

| HD5T-808-7 | HD5T | 96 | 96 | 84 | 134 | 165 | 650 | 448 |

| HD5T-808-8 | HD5T | 96 | 96 | 96 | 138 | 169 | 650 | 512 |

| HD5T-810-6 | HD5T | 96 | 120 | 72 | 134 | 189 | 650 | 480 |

| HD5T-810-7 | HD5T | 96 | 120 | 84 | 138 | 193 | 650 | 560 |

| HD5T-810-8 | HD5T | 96 | 120 | 96 | 138 | 193 | 650 | 640 |

| HD5T-812-6 | HD5T | 96 | 144 | 72 | 138 | 217 | 650 | 576 |

| HD5T-812-7 | HD5T | 96 | 144 | 84 | 138 | 240 | 650 | 672 |

| HD5T-812-8 | HD5T | 96 | 144 | 96 | 138 | 240 | 650 | 768 |

| HD5T-814-6 | HD5T | 96 | 168 | 72 | 138 | 264 | 650 | 672 |

| HD5T-814-7 | HD5T | 96 | 168 | 84 | 138 | 264 | 650 | 784 |

| HD5T-814-8 | HD5T | 96 | 168 | 96 | 142 | 264 | 650 | 896 |

| HD5T-816-6 | HD5T | 96 | 192 | 72 | 138 | 288 | 650 | 768 |

| HD5T-816-7 | HD5T | 96 | 192 | 84 | 142 | 288 | 650 | 896 |

| HD5T-816-8 | HD5T | 96 | 192 | 96 | 142 | 288 | 650 | 1024 |

| HD6B-404-6 | HD6B | 48 | 48 | 72 | 84 | 115 | 750 | 96 |

| HD6B-404-7 | HD6B | 48 | 48 | 84 | 84 | 115 | 750 | 112 |

| HD6B-404-8 | HD6B | 48 | 48 | 96 | 84 | 115 | 750 | 128 |

| HD6B-406-6 | HD6B | 48 | 72 | 72 | 84 | 139 | 750 | 144 |

| HD6B-406-7 | HD6B | 48 | 72 | 84 | 84 | 139 | 750 | 168 |

| HD6B-406-8 | HD6B | 48 | 72 | 96 | 84 | 139 | 750 | 192 |

| HD6B-408-6 | HD6B | 48 | 96 | 72 | 84 | 163 | 750 | 192 |

| HD6B-408-7 | HD6B | 48 | 96 | 84 | 84 | 167 | 750 | 224 |

| HD6B-408-8 | HD6B | 48 | 96 | 96 | 88 | 167 | 750 | 256 |

| HD6B-410-6 | HD6B | 48 | 120 | 72 | 88 | 191 | 750 | 240 |

| HD6B-410-7 | HD6B | 48 | 120 | 84 | 88 | 191 | 750 | 280 |

| HD6B-410-8 | HD6B | 48 | 120 | 96 | 88 | 191 | 750 | 320 |

| HD6B-412-6 | HD6B | 48 | 144 | 72 | 88 | 215 | 750 | 288 |

| HD6B-412-7 | HD6B | 48 | 144 | 84 | 88 | 215 | 750 | 336 |

| HD6B-412-8 | HD6B | 48 | 144 | 96 | 92 | 215 | 750 | 384 |

| HD6B-414-6 | HD6B | 48 | 168 | 72 | 88 | 239 | 750 | 336 |

| HD6B-414-7 | HD6B | 48 | 168 | 84 | 92 | 239 | 750 | 392 |

| HD6B-414-8 | HD6B | 48 | 168 | 96 | 88 | 239 | 750 | 448 |

| HD6B-416-6 | HD6B | 48 | 192 | 72 | 92 | 263 | 750 | 384 |

| HD6B-416-7 | HD6B | 48 | 192 | 84 | 88 | 263 | 750 | 448 |

| HD6B-416-8 | HD6B | 48 | 192 | 96 | 92 | 267 | 750 | 512 |

| HD6B-504-6 | HD6B | 60 | 48 | 72 | 96 | 115 | 750 | 120 |

| HD6B-504-7 | HD6B | 60 | 48 | 84 | 96 | 115 | 750 | 140 |

| HD6B-504-8 | HD6B | 60 | 48 | 96 | 96 | 115 | 750 | 160 |

| HD6B-506-6 | HD6B | 60 | 72 | 72 | 96 | 139 | 750 | 180 |

| HD6B-506-7 | HD6B | 60 | 72 | 84 | 96 | 143 | 750 | 210 |

| HD6B-506-8 | HD6B | 60 | 72 | 96 | 100 | 143 | 750 | 240 |

| HD6B-508-6 | HD6B | 60 | 96 | 72 | 100 | 167 | 750 | 240 |

| HD6B-508-7 | HD6B | 60 | 96 | 84 | 100 | 167 | 750 | 280 |

| HD6B-508-8 | HD6B | 60 | 96 | 96 | 100 | 167 | 750 | 320 |

| HD6B-510-6 | HD6B | 60 | 120 | 72 | 100 | 191 | 750 | 300 |

| HD6B-510-7 | HD6B | 60 | 120 | 84 | 104 | 191 | 750 | 350 |

| HD6B-510-8 | HD6B | 60 | 120 | 96 | 104 | 191 | 750 | 400 |

| HD6B-512-6 | HD6B | 60 | 144 | 72 | 104 | 215 | 750 | 360 |

| HD6B-512-7 | HD6B | 60 | 144 | 84 | 100 | 215 | 750 | 420 |

| HD6B-512-8 | HD6B | 60 | 144 | 96 | 104 | 219 | 750 | 480 |

| HD6B-514-6 | HD6B | 60 | 168 | 72 | 100 | 239 | 750 | 420 |

| HD6B-514-7 | HD6B | 60 | 168 | 84 | 104 | 243 | 750 | 490 |

| HD6B-514-8 | HD6B | 60 | 168 | 96 | 104 | 263 | 750 | 560 |

| HD6B-516-6 | HD6B | 60 | 192 | 72 | 104 | 267 | 750 | 480 |

| HD6B-516-7 | HD6B | 60 | 192 | 84 | 104 | 287 | 750 | 560 |

| HD6B-516-8 | HD6B | 60 | 192 | 96 | 104 | 290 | 750 | 640 |

| HD6B-604-6 | HD6B | 72 | 48 | 72 | 108 | 115 | 750 | 144 |

| HD6B-604-7 | HD6B | 72 | 48 | 84 | 108 | 115 | 750 | 168 |

| HD6B-604-8 | HD6B | 72 | 48 | 96 | 108 | 115 | 750 | 192 |

| HD6B-606-6 | HD6B | 72 | 72 | 72 | 108 | 143 | 750 | 216 |

| HD6B-606-7 | HD6B | 72 | 72 | 84 | 112 | 143 | 750 | 252 |

| HD6B-606-8 | HD6B | 72 | 72 | 96 | 112 | 143 | 750 | 288 |

| HD6B-608-6 | HD6B | 72 | 96 | 72 | 112 | 167 | 750 | 288 |

| HD6B-608-7 | HD6B | 72 | 96 | 84 | 116 | 167 | 750 | 336 |

| HD6B-608-8 | HD6B | 72 | 96 | 96 | 116 | 167 | 750 | 384 |

| HD6B-610-6 | HD6B | 72 | 120 | 72 | 116 | 191 | 750 | 360 |

| HD6B-610-7 | HD6B | 72 | 120 | 84 | 112 | 191 | 750 | 420 |

| HD6B-610-8 | HD6B | 72 | 120 | 96 | 116 | 195 | 750 | 480 |

| HD6B-612-6 | HD6B | 72 | 144 | 72 | 112 | 215 | 750 | 432 |

| HD6B-612-7 | HD6B | 72 | 144 | 84 | 116 | 219 | 750 | 504 |

| HD6B-612-8 | HD6B | 72 | 144 | 96 | 120 | 239 | 750 | 576 |

| HD6B-614-6 | HD6B | 72 | 168 | 72 | 116 | 243 | 750 | 504 |

| HD6B-614-7 | HD6B | 72 | 168 | 84 | 116 | 263 | 750 | 588 |

| HD6B-614-8 | HD6B | 72 | 168 | 96 | 116 | 266 | 750 | 672 |

| HD6B-616-6 | HD6B | 72 | 192 | 72 | 116 | 287 | 750 | 576 |

| HD6B-616-7 | HD6B | 72 | 192 | 84 | 116 | 290 | 750 | 672 |

| HD6B-616-8 | HD6B | 72 | 192 | 96 | 120 | 290 | 750 | 768 |

| HD6B-704-6 | HD6B | 84 | 48 | 72 | 120 | 115 | 750 | 168 |

| HD6B-704-7 | HD6B | 84 | 48 | 84 | 120 | 115 | 750 | 196 |

| HD6B-704-8 | HD6B | 84 | 48 | 96 | 124 | 119 | 750 | 224 |

| HD6B-706-6 | HD6B | 84 | 72 | 72 | 124 | 143 | 750 | 252 |

| HD6B-706-7 | HD6B | 84 | 72 | 84 | 124 | 143 | 750 | 294 |

| HD6B-706-8 | HD6B | 84 | 72 | 96 | 128 | 143 | 750 | 336 |

| HD6B-708-6 | HD6B | 84 | 96 | 72 | 124 | 167 | 750 | 336 |

| HD6B-708-7 | HD6B | 84 | 96 | 84 | 128 | 167 | 750 | 392 |

| HD6B-708-8 | HD6B | 84 | 96 | 96 | 128 | 167 | 750 | 448 |

| HD6B-710-6 | HD6B | 84 | 120 | 72 | 124 | 191 | 750 | 420 |

| HD6B-710-7 | HD6B | 84 | 120 | 84 | 128 | 195 | 750 | 490 |

| HD6B-710-8 | HD6B | 84 | 120 | 96 | 128 | 215 | 750 | 560 |

| HD6B-712-6 | HD6B | 84 | 144 | 72 | 128 | 219 | 750 | 504 |

| HD6B-712-7 | HD6B | 84 | 144 | 84 | 128 | 239 | 750 | 588 |

| HD6B-712-8 | HD6B | 84 | 144 | 96 | 128 | 242 | 750 | 672 |

| HD6B-714-6 | HD6B | 84 | 168 | 72 | 128 | 263 | 750 | 588 |

| HD6B-714-7 | HD6B | 84 | 168 | 84 | 128 | 266 | 750 | 686 |

| HD6B-714-8 | HD6B | 84 | 168 | 96 | 132 | 266 | 750 | 784 |

| HD6B-716-6 | HD6B | 84 | 192 | 72 | 128 | 725 | 750 | 672 |

| HD6B-716-7 | HD6B | 84 | 192 | 84 | 132 | 290 | 750 | 784 |

| HD6B-716-8 | HD6B | 84 | 192 | 96 | 136 | 290 | 750 | 896 |

| HD6B-804-6 | HD6B | 96 | 48 | 72 | 132 | 115 | 750 | 192 |

| HD6B-804-7 | HD6B | 96 | 48 | 84 | 132 | 119 | 750 | 224 |

| HD6B-804-8 | HD6B | 96 | 48 | 96 | 136 | 119 | 750 | 256 |

| HD6B-806-6 | HD6B | 96 | 72 | 72 | 136 | 143 | 750 | 288 |

| HD6B-806-7 | HD6B | 96 | 72 | 84 | 136 | 143 | 750 | 336 |

| HD6B-806-8 | HD6B | 96 | 72 | 96 | 140 | 143 | 750 | 384 |

| HD6B-808-6 | HD6B | 96 | 96 | 72 | 140 | 167 | 750 | 384 |

| HD6B-808-7 | HD6B | 96 | 96 | 84 | 136 | 167 | 750 | 448 |

| HD6B-808-8 | HD6B | 96 | 96 | 96 | 140 | 171 | 750 | 512 |

| HD6B-810-6 | HD6B | 96 | 120 | 72 | 140 | 195 | 750 | 480 |

| HD6B-810-7 | HD6B | 96 | 120 | 84 | 140 | 215 | 750 | 560 |

| HD6B-810-8 | HD6B | 96 | 120 | 96 | 140 | 218 | 750 | 640 |

| HD6B-812-6 | HD6B | 96 | 144 | 72 | 140 | 239 | 750 | 576 |

| HD6B-812-7 | HD6B | 96 | 144 | 84 | 140 | 242 | 750 | 672 |

| HD6B-812-8 | HD6B | 96 | 144 | 96 | 144 | 242 | 750 | 768 |

| HD6B-814-6 | HD6B | 96 | 168 | 72 | 140 | 266 | 750 | 672 |

| HD6B-814-7 | HD6B | 96 | 168 | 84 | 144 | 266 | 750 | 784 |

| HD6B-814-8 | HD6B | 96 | 168 | 96 | 148 | 266 | 750 | 896 |

| HD6B-816-6 | HD6B | 96 | 192 | 72 | 140 | 290 | 750 | 768 |

| HD6B-816-7 | HD6B | 96 | 192 | 84 | 144 | 290 | 750 | 896 |

| HD6B-816-8 | HD6B | 96 | 192 | 96 | 148 | 292 | 750 | 1024 |

| HD6B-613.5-10.5BIFG | HD6B | 72 | 160 | 132 | 135 | 288 | 650 | 797 |

| HD6B-615-10.5BIFG | HD6B | 72 | 195 | 132 | 135 | 328 | 650 | 1024 |

| HD6T-404-6 | HD6T | 48 | 48 | 72 | 84 | 115 | 750 | 96 |

| HD6T-404-7 | HD6T | 48 | 48 | 84 | 84 | 115 | 750 | 112 |

| HD6T-404-8 | HD6T | 48 | 48 | 96 | 84 | 115 | 750 | 128 |

| HD6T-406-6 | HD6T | 48 | 72 | 72 | 84 | 139 | 750 | 144 |

| HD6T-406-7 | HD6T | 48 | 72 | 84 | 84 | 139 | 750 | 168 |

| HD6T-406-8 | HD6T | 48 | 72 | 96 | 84 | 139 | 750 | 192 |

| HD6T-408-6 | HD6T | 48 | 96 | 72 | 84 | 163 | 750 | 192 |

| HD6T-408-7 | HD6T | 48 | 96 | 84 | 84 | 167 | 750 | 224 |

| HD6T-408-8 | HD6T | 48 | 96 | 96 | 88 | 167 | 750 | 256 |

| HD6T-410-6 | HD6T | 48 | 120 | 72 | 88 | 191 | 750 | 240 |

| HD6T-410-7 | HD6T | 48 | 120 | 84 | 88 | 191 | 750 | 280 |

| HD6T-410-8 | HD6T | 48 | 120 | 96 | 88 | 191 | 750 | 320 |

| HD6T-412-6 | HD6T | 48 | 144 | 72 | 88 | 215 | 750 | 288 |

| HD6T-412-7 | HD6T | 48 | 144 | 84 | 88 | 215 | 750 | 336 |

| HD6T-412-8 | HD6T | 48 | 144 | 96 | 92 | 215 | 750 | 384 |

| HD6T-414-6 | HD6T | 48 | 168 | 72 | 88 | 239 | 750 | 336 |

| HD6T-414-7 | HD6T | 48 | 168 | 84 | 92 | 239 | 750 | 392 |

| HD6T-414-8 | HD6T | 48 | 168 | 96 | 88 | 239 | 750 | 448 |

| HD6T-416-6 | HD6T | 48 | 192 | 72 | 92 | 263 | 750 | 384 |

| HD6T-416-7 | HD6T | 48 | 192 | 84 | 88 | 263 | 750 | 448 |

| HD6T-416-8 | HD6T | 48 | 192 | 96 | 92 | 267 | 750 | 512 |

| HD6T-504-6 | HD6T | 60 | 48 | 72 | 96 | 115 | 750 | 120 |

| HD6T-504-7 | HD6T | 60 | 48 | 84 | 96 | 115 | 750 | 140 |

| HD6T-504-8 | HD6T | 60 | 48 | 96 | 96 | 115 | 750 | 160 |

| HD6T-506-6 | HD6T | 60 | 72 | 72 | 96 | 139 | 750 | 180 |

| HD6T-506-7 | HD6T | 60 | 72 | 84 | 96 | 143 | 750 | 210 |

| HD6T-506-8 | HD6T | 60 | 72 | 96 | 100 | 143 | 750 | 240 |

| HD6T-508-6 | HD6T | 60 | 96 | 72 | 100 | 167 | 750 | 240 |

| HD6T-508-7 | HD6T | 60 | 96 | 84 | 100 | 167 | 750 | 280 |

| HD6T-508-8 | HD6T | 60 | 96 | 96 | 100 | 167 | 750 | 320 |

| HD6T-510-6 | HD6T | 60 | 120 | 72 | 100 | 191 | 750 | 300 |

| HD6T-510-7 | HD6T | 60 | 120 | 84 | 104 | 191 | 750 | 350 |

| HD6T-510-8 | HD6T | 60 | 120 | 96 | 104 | 191 | 750 | 400 |

| HD6T-512-6 | HD6T | 60 | 144 | 72 | 104 | 215 | 750 | 360 |

| HD6T-512-7 | HD6T | 60 | 144 | 84 | 100 | 215 | 750 | 420 |

| HD6T-512-8 | HD6T | 60 | 144 | 96 | 104 | 219 | 750 | 480 |

| HD6T-514-6 | HD6T | 60 | 168 | 72 | 100 | 239 | 750 | 420 |

| HD6T-514-7 | HD6T | 60 | 168 | 84 | 104 | 243 | 750 | 490 |

| HD6T-514-8 | HD6T | 60 | 168 | 96 | 104 | 263 | 750 | 560 |

| HD6T-516-6 | HD6T | 60 | 192 | 72 | 104 | 267 | 750 | 480 |

| HD6T-516-7 | HD6T | 60 | 192 | 84 | 104 | 287 | 750 | 560 |

| HD6T-516-8 | HD6T | 60 | 192 | 96 | 104 | 290 | 750 | 640 |

| HD6T-604-6 | HD6T | 72 | 48 | 72 | 108 | 115 | 750 | 144 |

| HD6T-604-7 | HD6T | 72 | 48 | 84 | 108 | 115 | 750 | 168 |

| HD6T-604-8 | HD6T | 72 | 48 | 96 | 108 | 115 | 750 | 192 |

| HD6T-606-6 | HD6T | 72 | 72 | 72 | 108 | 143 | 750 | 216 |

| HD6T-606-7 | HD6T | 72 | 72 | 84 | 112 | 143 | 750 | 252 |

| HD6T-606-8 | HD6T | 72 | 72 | 96 | 112 | 143 | 750 | 288 |

| HD6T-608-6 | HD6T | 72 | 96 | 72 | 112 | 167 | 750 | 288 |

| HD6T-608-7 | HD6T | 72 | 96 | 84 | 116 | 167 | 750 | 336 |

| HD6T-608-8 | HD6T | 72 | 96 | 96 | 116 | 167 | 750 | 384 |

| HD6T-610-6 | HD6T | 72 | 120 | 72 | 116 | 191 | 750 | 360 |

| HD6T-610-7 | HD6T | 72 | 120 | 84 | 112 | 191 | 750 | 420 |

| HD6T-610-8 | HD6T | 72 | 120 | 96 | 116 | 195 | 750 | 480 |

| HD6T-612-6 | HD6T | 72 | 144 | 72 | 112 | 215 | 750 | 432 |

| HD6T-612-7 | HD6T | 72 | 144 | 84 | 116 | 219 | 750 | 504 |

| HD6T-612-8 | HD6T | 72 | 144 | 96 | 120 | 239 | 750 | 576 |

| HD6T-614-6 | HD6T | 72 | 168 | 72 | 116 | 243 | 750 | 504 |

| HD6T-614-7 | HD6T | 72 | 168 | 84 | 116 | 263 | 750 | 588 |

| HD6T-614-8 | HD6T | 72 | 168 | 96 | 116 | 266 | 750 | 672 |

| HD6T-616-6 | HD6T | 72 | 192 | 72 | 116 | 287 | 750 | 576 |

| HD6T-616-7 | HD6T | 72 | 192 | 84 | 116 | 290 | 750 | 672 |

| HD6T-616-8 | HD6T | 72 | 192 | 96 | 120 | 290 | 750 | 768 |

| HD6T-704-6 | HD6T | 84 | 48 | 72 | 120 | 115 | 750 | 168 |

| HD6T-704-7 | HD6T | 84 | 48 | 84 | 120 | 115 | 750 | 196 |

| HD6T-704-8 | HD6T | 84 | 48 | 96 | 124 | 119 | 750 | 224 |

| HD6T-706-6 | HD6T | 84 | 72 | 72 | 124 | 143 | 750 | 252 |

| HD6T-706-7 | HD6T | 84 | 72 | 84 | 124 | 143 | 750 | 294 |

| HD6T-706-8 | HD6T | 84 | 72 | 96 | 128 | 143 | 750 | 336 |

| HD6T-708-6 | HD6T | 84 | 96 | 72 | 124 | 167 | 750 | 336 |

| HD6T-708-7 | HD6T | 84 | 96 | 84 | 128 | 167 | 750 | 392 |

| HD6T-708-8 | HD6T | 84 | 96 | 96 | 128 | 167 | 750 | 448 |

| HD6T-710-6 | HD6T | 84 | 120 | 72 | 124 | 191 | 750 | 420 |

| HD6T-710-7 | HD6T | 84 | 120 | 84 | 128 | 195 | 750 | 490 |

| HD6T-710-8 | HD6T | 84 | 120 | 96 | 128 | 215 | 750 | 560 |

| HD6T-712-6 | HD6T | 84 | 144 | 72 | 128 | 219 | 750 | 504 |

| HD6T-712-7 | HD6T | 84 | 144 | 84 | 128 | 239 | 750 | 588 |

| HD6T-712-8 | HD6T | 84 | 144 | 96 | 128 | 242 | 750 | 672 |

| HD6T-714-6 | HD6T | 84 | 168 | 72 | 128 | 263 | 750 | 588 |

| HD6T-714-7 | HD6T | 84 | 168 | 84 | 128 | 266 | 750 | 686 |

| HD6T-714-8 | HD6T | 84 | 168 | 96 | 132 | 266 | 750 | 784 |

| HD6T-716-6 | HD6T | 84 | 192 | 72 | 128 | 725 | 750 | 672 |

| HD6T-716-7 | HD6T | 84 | 192 | 84 | 132 | 290 | 750 | 784 |

| HD6T-716-8 | HD6T | 84 | 192 | 96 | 136 | 290 | 750 | 896 |

| HD6T-804-6 | HD6T | 96 | 48 | 72 | 132 | 115 | 750 | 192 |

| HD6T-804-7 | HD6T | 96 | 48 | 84 | 132 | 119 | 750 | 224 |

| HD6T-804-8 | HD6T | 96 | 48 | 96 | 136 | 119 | 750 | 256 |

| HD6T-806-6 | HD6T | 96 | 72 | 72 | 136 | 143 | 750 | 288 |

| HD6T-806-7 | HD6T | 96 | 72 | 84 | 136 | 143 | 750 | 336 |

| HD6T-806-8 | HD6T | 96 | 72 | 96 | 140 | 143 | 750 | 384 |

| HD6T-808-6 | HD6T | 96 | 96 | 72 | 140 | 167 | 750 | 384 |

| HD6T-808-7 | HD6T | 96 | 96 | 84 | 136 | 167 | 750 | 448 |

| HD6T-808-8 | HD6T | 96 | 96 | 96 | 140 | 171 | 750 | 512 |

| HD6T-810-6 | HD6T | 96 | 120 | 72 | 140 | 195 | 750 | 480 |

| HD6T-810-7 | HD6T | 96 | 120 | 84 | 140 | 215 | 750 | 560 |

| HD6T-810-8 | HD6T | 96 | 120 | 96 | 140 | 218 | 750 | 640 |

| HD6T-812-6 | HD6T | 96 | 144 | 72 | 140 | 239 | 750 | 576 |

| HD6T-812-7 | HD6T | 96 | 144 | 84 | 140 | 242 | 750 | 672 |

| HD6T-812-8 | HD6T | 96 | 144 | 96 | 144 | 242 | 750 | 768 |

| HD6T-814-6 | HD6T | 96 | 168 | 72 | 140 | 266 | 750 | 672 |

| HD6T-814-7 | HD6T | 96 | 168 | 84 | 144 | 266 | 750 | 784 |

| HD6T-814-8 | HD6T | 96 | 168 | 96 | 148 | 266 | 750 | 896 |

| HD6T-816-6 | HD6T | 96 | 192 | 72 | 140 | 290 | 750 | 768 |

| HD6T-816-7 | HD6T | 96 | 192 | 84 | 144 | 290 | 750 | 896 |

| HD6T-816-8 | HD6T | 96 | 192 | 96 | 148 | 292 | 750 | 1024 |

| HD7B-404-6 | HD7B | 48 | 48 | 72 | 86 | 117 | 850 | 96 |

| HD7B-404-7 | HD7B | 48 | 48 | 84 | 86 | 117 | 850 | 112 |

| HD7B-404-8 | HD7B | 48 | 48 | 96 | 86 | 117 | 850 | 128 |

| HD7B-406-6 | HD7B | 48 | 72 | 72 | 86 | 141 | 850 | 144 |

| HD7B-406-7 | HD7B | 48 | 72 | 84 | 86 | 141 | 850 | 168 |

| HD7B-406-8 | HD7B | 48 | 72 | 96 | 86 | 145 | 850 | 192 |

| HD7B-408-6 | HD7B | 48 | 96 | 72 | 86 | 169 | 850 | 192 |

| HD7B-408-7 | HD7B | 48 | 96 | 84 | 86 | 169 | 850 | 224 |

| HD7B-408-8 | HD7B | 48 | 96 | 96 | 90 | 169 | 850 | 256 |

| HD7B-410-6 | HD7B | 48 | 120 | 72 | 90 | 193 | 850 | 240 |

| HD7B-410-7 | HD7B | 48 | 120 | 84 | 90 | 193 | 850 | 280 |

| HD7B-410-8 | HD7B | 48 | 120 | 96 | 90 | 193 | 850 | 320 |

| HD7B-412-6 | HD7B | 48 | 144 | 72 | 90 | 217 | 850 | 288 |

| HD7B-412-7 | HD7B | 48 | 144 | 84 | 90 | 217 | 850 | 336 |

| HD7B-412-8 | HD7B | 48 | 144 | 96 | 94 | 217 | 850 | 384 |

| HD7B-414-6 | HD7B | 48 | 168 | 72 | 90 | 241 | 850 | 336 |

| HD7B-414-7 | HD7B | 48 | 168 | 84 | 94 | 261 | 850 | 392 |

| HD7B-414-8 | HD7B | 48 | 168 | 96 | 90 | 265 | 850 | 448 |

| HD7B-416-6 | HD7B | 48 | 192 | 72 | 94 | 265 | 850 | 384 |

| HD7B-416-7 | HD7B | 48 | 192 | 84 | 90 | 269 | 850 | 448 |

| HD7B-416-8 | HD7B | 48 | 192 | 96 | 94 | 289 | 850 | 512 |

| HD7B-504-6 | HD7B | 60 | 48 | 72 | 98 | 117 | 850 | 120 |

| HD7B-504-7 | HD7B | 60 | 48 | 84 | 98 | 117 | 850 | 140 |

| HD7B-504-8 | HD7B | 60 | 48 | 96 | 98 | 117 | 850 | 160 |

| HD7B-506-6 | HD7B | 60 | 72 | 72 | 98 | 141 | 850 | 180 |

| HD7B-506-7 | HD7B | 60 | 72 | 84 | 98 | 145 | 850 | 210 |

| HD7B-506-8 | HD7B | 60 | 72 | 96 | 102 | 145 | 850 | 240 |

| HD7B-508-6 | HD7B | 60 | 96 | 72 | 102 | 169 | 850 | 240 |

| HD7B-508-7 | HD7B | 60 | 96 | 84 | 102 | 169 | 850 | 280 |

| HD7B-508-8 | HD7B | 60 | 96 | 96 | 102 | 169 | 850 | 320 |

| HD7B-510-6 | HD7B | 60 | 120 | 72 | 102 | 193 | 850 | 300 |

| HD7B-510-7 | HD7B | 60 | 120 | 84 | 106 | 193 | 850 | 350 |

| HD7B-510-8 | HD7B | 60 | 120 | 96 | 106 | 193 | 850 | 400 |

| HD7B-512-6 | HD7B | 60 | 144 | 72 | 106 | 217 | 850 | 360 |

| HD7B-512-7 | HD7B | 60 | 144 | 84 | 102 | 241 | 850 | 420 |

| HD7B-512-8 | HD7B | 60 | 144 | 96 | 106 | 241 | 850 | 480 |

| HD7B-514-6 | HD7B | 60 | 168 | 72 | 102 | 245 | 850 | 420 |

| HD7B-514-7 | HD7B | 60 | 168 | 84 | 106 | 265 | 850 | 490 |

| HD7B-514-8 | HD7B | 60 | 168 | 96 | 106 | 268 | 850 | 560 |

| HD7B-516-6 | HD7B | 60 | 192 | 72 | 106 | 289 | 850 | 480 |

| HD7B-516-7 | HD7B | 60 | 192 | 84 | 106 | 292 | 850 | 560 |

| HD7B-516-8 | HD7B | 60 | 192 | 96 | 106 | 292 | 850 | 640 |

| HD7B-604-6 | HD7B | 72 | 48 | 72 | 110 | 117 | 850 | 144 |

| HD7B-604-7 | HD7B | 72 | 48 | 84 | 110 | 117 | 850 | 168 |

| HD7B-604-8 | HD7B | 72 | 48 | 96 | 110 | 121 | 850 | 192 |

| HD7B-606-6 | HD7B | 72 | 72 | 72 | 110 | 145 | 850 | 216 |

| HD7B-606-7 | HD7B | 72 | 72 | 84 | 114 | 145 | 850 | 252 |

| HD7B-606-8 | HD7B | 72 | 72 | 96 | 114 | 145 | 850 | 288 |

| HD7B-608-6 | HD7B | 72 | 96 | 72 | 114 | 169 | 850 | 288 |

| HD7B-608-7 | HD7B | 72 | 96 | 84 | 118 | 169 | 850 | 336 |

| HD7B-608-8 | HD7B | 72 | 96 | 96 | 118 | 169 | 850 | 384 |

| HD7B-610-6 | HD7B | 72 | 120 | 72 | 118 | 193 | 850 | 360 |

| HD7B-610-7 | HD7B | 72 | 120 | 84 | 114 | 197 | 850 | 420 |

| HD7B-610-8 | HD7B | 72 | 120 | 96 | 118 | 217 | 850 | 480 |

| HD7B-612-6 | HD7B | 72 | 144 | 72 | 114 | 241 | 850 | 432 |

| HD7B-612-7 | HD7B | 72 | 144 | 84 | 118 | 241 | 850 | 504 |

| HD7B-612-8 | HD7B | 72 | 144 | 96 | 122 | 244 | 850 | 576 |

| HD7B-614-6 | HD7B | 72 | 168 | 72 | 118 | 265 | 850 | 504 |

| HD7B-614-7 | HD7B | 72 | 168 | 84 | 118 | 268 | 850 | 588 |

| HD7B-614-8 | HD7B | 72 | 168 | 96 | 118 | 268 | 850 | 672 |

| HD7B-616-6 | HD7B | 72 | 192 | 72 | 118 | 292 | 850 | 576 |

| HD7B-616-7 | HD7B | 72 | 192 | 84 | 118 | 292 | 850 | 672 |

| HD7B-616-8 | HD7B | 72 | 192 | 96 | 122 | 292 | 850 | 768 |

| HD7B-704-6 | HD7B | 84 | 48 | 72 | 122 | 117 | 850 | 168 |

| HD7B-704-7 | HD7B | 84 | 48 | 84 | 122 | 121 | 850 | 196 |

| HD7B-704-8 | HD7B | 84 | 48 | 96 | 126 | 121 | 850 | 224 |

| HD7B-706-6 | HD7B | 84 | 72 | 72 | 126 | 145 | 850 | 252 |

| HD7B-706-7 | HD7B | 84 | 72 | 84 | 126 | 145 | 850 | 294 |

| HD7B-706-8 | HD7B | 84 | 72 | 96 | 130 | 145 | 850 | 336 |

| HD7B-708-6 | HD7B | 84 | 96 | 72 | 126 | 169 | 850 | 336 |

| HD7B-708-7 | HD7B | 84 | 96 | 84 | 130 | 189 | 850 | 392 |

| HD7B-708-8 | HD7B | 84 | 96 | 96 | 130 | 193 | 850 | 448 |

| HD7B-710-6 | HD7B | 84 | 120 | 72 | 126 | 197 | 850 | 420 |

| HD7B-710-7 | HD7B | 84 | 120 | 84 | 130 | 217 | 850 | 490 |

| HD7B-710-8 | HD7B | 84 | 120 | 96 | 130 | 220 | 850 | 560 |

| HD7B-712-6 | HD7B | 84 | 144 | 72 | 130 | 241 | 850 | 504 |

| HD7B-712-7 | HD7B | 84 | 144 | 84 | 130 | 244 | 850 | 588 |

| HD7B-712-8 | HD7B | 84 | 144 | 96 | 130 | 244 | 850 | 672 |

| HD7B-714-6 | HD7B | 84 | 168 | 72 | 130 | 268 | 850 | 588 |

| HD7B-714-7 | HD7B | 84 | 168 | 84 | 130 | 268 | 850 | 686 |

| HD7B-714-8 | HD7B | 84 | 168 | 96 | 134 | 268 | 850 | 784 |

| HD7B-716-6 | HD7B | 84 | 192 | 72 | 130 | 292 | 850 | 672 |

| HD7B-716-7 | HD7B | 84 | 192 | 84 | 134 | 292 | 850 | 784 |

| HD7B-716-8 | HD7B | 84 | 192 | 96 | 138 | 292 | 850 | 896 |

| HD7B-804-6 | HD7B | 96 | 48 | 72 | 134 | 121 | 850 | 192 |

| HD7B-804-7 | HD7B | 96 | 48 | 84 | 134 | 121 | 850 | 224 |

| HD7B-804-8 | HD7B | 96 | 48 | 96 | 138 | 121 | 850 | 256 |

| HD7B-806-6 | HD7B | 96 | 72 | 72 | 138 | 145 | 850 | 288 |

| HD7B-806-7 | HD7B | 96 | 72 | 84 | 138 | 145 | 850 | 336 |

| HD7B-806-8 | HD7B | 96 | 72 | 96 | 142 | 145 | 850 | 384 |

| HD7B-808-6 | HD7B | 96 | 96 | 72 | 142 | 169 | 850 | 384 |

| HD7B-808-7 | HD7B | 96 | 96 | 84 | 138 | 173 | 850 | 448 |

| HD7B-808-8 | HD7B | 96 | 96 | 96 | 142 | 193 | 850 | 512 |

| HD7B-810-6 | HD7B | 96 | 120 | 72 | 142 | 217 | 850 | 480 |

| HD7B-810-7 | HD7B | 96 | 120 | 84 | 142 | 220 | 850 | 560 |

| HD7B-810-8 | HD7B | 96 | 120 | 96 | 142 | 220 | 850 | 640 |

| HD7B-812-6 | HD7B | 96 | 144 | 72 | 142 | 244 | 850 | 576 |

| HD7B-812-7 | HD7B | 96 | 144 | 84 | 142 | 244 | 850 | 672 |

| HD7B-812-8 | HD7B | 96 | 144 | 96 | 146 | 244 | 850 | 768 |

| HD7B-814-6 | HD7B | 96 | 168 | 72 | 142 | 268 | 850 | 672 |

| HD7B-814-7 | HD7B | 96 | 168 | 84 | 146 | 268 | 850 | 784 |

| HD7B-814-8 | HD7B | 96 | 168 | 96 | 150 | 268 | 850 | 896 |

| HD7B-816-6 | HD7B | 96 | 192 | 72 | 142 | 292 | 850 | 768 |

| HD7B-816-7 | HD7B | 96 | 192 | 84 | 146 | 292 | 850 | 896 |

| HD7B-816-8 | HD7B | 96 | 192 | 96 | 150 | 294 | 850 | 1024 |

| HD7T-404-6 | HD7T | 48 | 48 | 72 | 86 | 117 | 850 | 96 |

| HD7T-404-7 | HD7T | 48 | 48 | 84 | 86 | 117 | 850 | 112 |

| HD7T-404-8 | HD7T | 48 | 48 | 96 | 86 | 117 | 850 | 128 |

| HD7T-406-6 | HD7T | 48 | 72 | 72 | 86 | 141 | 850 | 144 |

| HD7T-406-7 | HD7T | 48 | 72 | 84 | 86 | 141 | 850 | 168 |

| HD7T-406-8 | HD7T | 48 | 72 | 96 | 86 | 145 | 850 | 192 |

| HD7T-408-6 | HD7T | 48 | 96 | 72 | 86 | 169 | 850 | 192 |

| HD7T-408-7 | HD7T | 48 | 96 | 84 | 86 | 169 | 850 | 224 |

| HD7T-408-8 | HD7T | 48 | 96 | 96 | 90 | 169 | 850 | 256 |

| HD7T-410-6 | HD7T | 48 | 120 | 72 | 90 | 193 | 850 | 240 |

| HD7T-410-7 | HD7T | 48 | 120 | 84 | 90 | 193 | 850 | 280 |

| HD7T-410-8 | HD7T | 48 | 120 | 96 | 90 | 193 | 850 | 320 |

| HD7T-412-6 | HD7T | 48 | 144 | 72 | 90 | 217 | 850 | 288 |

| HD7T-412-7 | HD7T | 48 | 144 | 84 | 90 | 217 | 850 | 336 |

| HD7T-412-8 | HD7T | 48 | 144 | 96 | 94 | 217 | 850 | 384 |

| HD7T-414-6 | HD7T | 48 | 168 | 72 | 90 | 241 | 850 | 336 |

| HD7T-414-7 | HD7T | 48 | 168 | 84 | 94 | 261 | 850 | 392 |

| HD7T-414-8 | HD7T | 48 | 168 | 96 | 90 | 265 | 850 | 448 |

| HD7T-416-6 | HD7T | 48 | 192 | 72 | 94 | 265 | 850 | 384 |

| HD7T-416-7 | HD7T | 48 | 192 | 84 | 90 | 269 | 850 | 448 |

| HD7T-416-8 | HD7T | 48 | 192 | 96 | 94 | 289 | 850 | 512 |

| HD7T-504-6 | HD7T | 60 | 48 | 72 | 98 | 117 | 850 | 120 |

| HD7T-504-7 | HD7T | 60 | 48 | 84 | 98 | 117 | 850 | 140 |

| HD7T-504-8 | HD7T | 60 | 48 | 96 | 98 | 117 | 850 | 160 |

| HD7T-506-6 | HD7T | 60 | 72 | 72 | 98 | 141 | 850 | 180 |

| HD7T-506-7 | HD7T | 60 | 72 | 84 | 98 | 145 | 850 | 210 |

| HD7T-506-8 | HD7T | 60 | 72 | 96 | 102 | 145 | 850 | 240 |

| HD7T-508-6 | HD7T | 60 | 96 | 72 | 102 | 169 | 850 | 240 |

| HD7T-508-7 | HD7T | 60 | 96 | 84 | 102 | 169 | 850 | 280 |

| HD7T-508-8 | HD7T | 60 | 96 | 96 | 102 | 169 | 850 | 320 |

| HD7T-510-6 | HD7T | 60 | 120 | 72 | 102 | 193 | 850 | 300 |

| HD7T-510-7 | HD7T | 60 | 120 | 84 | 106 | 193 | 850 | 350 |

| HD7T-510-8 | HD7T | 60 | 120 | 96 | 106 | 193 | 850 | 400 |

| HD7T-512-6 | HD7T | 60 | 144 | 72 | 106 | 217 | 850 | 360 |

| HD7T-512-7 | HD7T | 60 | 144 | 84 | 102 | 241 | 850 | 420 |

| HD7T-512-8 | HD7T | 60 | 144 | 96 | 106 | 241 | 850 | 480 |

| HD7T-514-6 | HD7T | 60 | 168 | 72 | 102 | 245 | 850 | 420 |

| HD7T-514-7 | HD7T | 60 | 168 | 84 | 106 | 265 | 850 | 490 |

| HD7T-514-8 | HD7T | 60 | 168 | 96 | 106 | 268 | 850 | 560 |

| HD7T-516-6 | HD7T | 60 | 192 | 72 | 106 | 289 | 850 | 480 |

| HD7T-516-7 | HD7T | 60 | 192 | 84 | 106 | 292 | 850 | 560 |

| HD7T-516-8 | HD7T | 60 | 192 | 96 | 106 | 292 | 850 | 640 |

| HD7T-604-6 | HD7T | 72 | 48 | 72 | 110 | 117 | 850 | 144 |

| HD7T-604-7 | HD7T | 72 | 48 | 84 | 110 | 117 | 850 | 168 |

| HD7T-604-8 | HD7T | 72 | 48 | 96 | 110 | 121 | 850 | 192 |

| HD7T-606-6 | HD7T | 72 | 72 | 72 | 110 | 145 | 850 | 216 |

| HD7T-606-7 | HD7T | 72 | 72 | 84 | 114 | 145 | 850 | 252 |

| HD7T-606-8 | HD7T | 72 | 72 | 96 | 114 | 145 | 850 | 288 |

| HD7T-608-6 | HD7T | 72 | 96 | 72 | 114 | 169 | 850 | 288 |

| HD7T-608-7 | HD7T | 72 | 96 | 84 | 118 | 169 | 850 | 336 |

| HD7T-608-8 | HD7T | 72 | 96 | 96 | 118 | 169 | 850 | 384 |

| HD7T-610-6 | HD7T | 72 | 120 | 72 | 118 | 193 | 850 | 360 |

| HD7T-610-7 | HD7T | 72 | 120 | 84 | 114 | 197 | 850 | 420 |

| HD7T-610-8 | HD7T | 72 | 120 | 96 | 118 | 217 | 850 | 480 |

| HD7T-612-6 | HD7T | 72 | 144 | 72 | 114 | 241 | 850 | 432 |

| HD7T-612-7 | HD7T | 72 | 144 | 84 | 118 | 241 | 850 | 504 |

| HD7T-612-8 | HD7T | 72 | 144 | 96 | 122 | 244 | 850 | 576 |

| HD7T-614-6 | HD7T | 72 | 168 | 72 | 118 | 265 | 850 | 504 |

| HD7T-614-7 | HD7T | 72 | 168 | 84 | 118 | 268 | 850 | 588 |

| HD7T-614-8 | HD7T | 72 | 168 | 96 | 118 | 268 | 850 | 672 |

| HD7T-616-6 | HD7T | 72 | 192 | 72 | 118 | 292 | 850 | 576 |

| HD7T-616-7 | HD7T | 72 | 192 | 84 | 118 | 292 | 850 | 672 |

| HD7T-616-8 | HD7T | 72 | 192 | 96 | 122 | 292 | 850 | 768 |

| HD7T-704-6 | HD7T | 84 | 48 | 72 | 122 | 117 | 850 | 168 |

| HD7T-704-7 | HD7T | 84 | 48 | 84 | 122 | 121 | 850 | 196 |

| HD7T-704-8 | HD7T | 84 | 48 | 96 | 126 | 121 | 850 | 224 |

| HD7T-706-6 | HD7T | 84 | 72 | 72 | 126 | 145 | 850 | 252 |

| HD7T-706-7 | HD7T | 84 | 72 | 84 | 126 | 145 | 850 | 294 |

| HD7T-706-8 | HD7T | 84 | 72 | 96 | 130 | 145 | 850 | 336 |

| HD7T-708-6 | HD7T | 84 | 96 | 72 | 126 | 169 | 850 | 336 |

| HD7T-708-7 | HD7T | 84 | 96 | 84 | 130 | 189 | 850 | 392 |

| HD7T-708-8 | HD7T | 84 | 96 | 96 | 130 | 193 | 850 | 448 |

| HD7T-710-6 | HD7T | 84 | 120 | 72 | 126 | 197 | 850 | 420 |

| HD7T-710-7 | HD7T | 84 | 120 | 84 | 130 | 217 | 850 | 490 |

| HD7T-710-8 | HD7T | 84 | 120 | 96 | 130 | 220 | 850 | 560 |

| HD7T-712-6 | HD7T | 84 | 144 | 72 | 130 | 241 | 850 | 504 |

| HD7T-712-7 | HD7T | 84 | 144 | 84 | 130 | 244 | 850 | 588 |

| HD7T-712-8 | HD7T | 84 | 144 | 96 | 130 | 244 | 850 | 672 |

| HD7T-714-6 | HD7T | 84 | 168 | 72 | 130 | 268 | 850 | 588 |

| HD7T-714-7 | HD7T | 84 | 168 | 84 | 130 | 268 | 850 | 686 |

| HD7T-714-8 | HD7T | 84 | 168 | 96 | 134 | 268 | 850 | 784 |

| HD7T-716-6 | HD7T | 84 | 192 | 72 | 130 | 292 | 850 | 672 |

| HD7T-716-7 | HD7T | 84 | 192 | 84 | 134 | 292 | 850 | 784 |

| HD7T-716-8 | HD7T | 84 | 192 | 96 | 138 | 292 | 850 | 896 |

| HD7T-804-6 | HD7T | 96 | 48 | 72 | 134 | 121 | 850 | 192 |

| HD7T-804-7 | HD7T | 96 | 48 | 84 | 134 | 121 | 850 | 224 |

| HD7T-804-8 | HD7T | 96 | 48 | 96 | 138 | 121 | 850 | 256 |

| HD7T-806-6 | HD7T | 96 | 72 | 72 | 138 | 145 | 850 | 288 |

| HD7T-806-7 | HD7T | 96 | 72 | 84 | 138 | 145 | 850 | 336 |

| HD7T-806-8 | HD7T | 96 | 72 | 96 | 142 | 145 | 850 | 384 |

| HD7T-808-6 | HD7T | 96 | 96 | 72 | 142 | 169 | 850 | 384 |

| HD7T-808-7 | HD7T | 96 | 96 | 84 | 138 | 173 | 850 | 448 |

| HD7T-808-8 | HD7T | 96 | 96 | 96 | 142 | 193 | 850 | 512 |

| HD7T-810-6 | HD7T | 96 | 120 | 72 | 142 | 217 | 850 | 480 |

| HD7T-810-7 | HD7T | 96 | 120 | 84 | 142 | 220 | 850 | 560 |

| HD7T-810-8 | HD7T | 96 | 120 | 96 | 142 | 220 | 850 | 640 |

| HD7T-812-6 | HD7T | 96 | 144 | 72 | 142 | 244 | 850 | 576 |

| HD7T-812-7 | HD7T | 96 | 144 | 84 | 142 | 244 | 850 | 672 |

| HD7T-812-8 | HD7T | 96 | 144 | 96 | 146 | 244 | 850 | 768 |

| HD7T-814-6 | HD7T | 96 | 168 | 72 | 142 | 268 | 850 | 672 |

| HD7T-814-7 | HD7T | 96 | 168 | 84 | 146 | 268 | 850 | 784 |

| HD7T-814-8 | HD7T | 96 | 168 | 96 | 150 | 268 | 850 | 896 |

| HD7T-816-6 | HD7T | 96 | 192 | 72 | 142 | 292 | 850 | 768 |

| HD7T-816-7 | HD7T | 96 | 192 | 84 | 146 | 292 | 850 | 896 |

| HD7T-816-8 | HD7T | 96 | 192 | 96 | 150 | 294 | 850 | 1024 |

| HT10B-404-6 | HT10B | 48 | 48 | 72 | 87 | 149 | 1000 | 96 |

| HT10B-506-6 | HT10B | 60 | 72 | 72 | 99 | 174 | 1000 | 144 |

| HT10B-508-6 | HT10B | 60 | 96 | 72 | 105 | 197 | 1000 | 192 |

| HT10B-610-6 | HT10B | 72 | 120 | 72 | 117 | 220 | 1000 | 240 |

| HT10T-404-6 | HT10T | 48 | 48 | 72 | 1000 | 96 | ||

| HT10T-506-6 | HT10T | 60 | 72 | 72 | 1000 | 180 | ||

| HT10T-508-6 | HT10T | 60 | 96 | 72 | 1000 | 240 | ||

| HT10T-610-6 | HT10T | 72 | 120 | 72 | 1000 | 360 | ||

| HT12B-404-6 | HT12B | 48 | 48 | 72 | 92 | 154 | 1250 | 96 |

| HT12B-506-6 | HT12B | 60 | 72 | 72 | 104 | 179 | 1250 | 180 |

| HT12B-508-6 | HT12B | 60 | 96 | 72 | 110 | 202 | 1250 | 240 |

| HT12B-610-6 | HT12B | 72 | 120 | 72 | 122 | 225 | 1250 | 360 |

| PCO-406-6 | PCO | 48 | 72 | 72 | 80 | 83 | 500 | 144 |

| PCO-406-7 | PCO | 48 | 72 | 84 | 80 | 83 | 500 | 168 |

| PCO-406-8 | PCO | 48 | 72 | 96 | 80 | 83 | 500 | 192 |

| PCO-408-6 | PCO | 48 | 96 | 72 | 80 | 107 | 500 | 192 |

| PCO-408-7 | PCO | 48 | 96 | 84 | 80 | 107 | 500 | 224 |

| PCO-408-8 | PCO | 48 | 96 | 96 | 80 | 107 | 500 | 256 |

| PCO-410-6 | PCO | 48 | 120 | 72 | 80 | 131 | 500 | 240 |

| PCO-410-7 | PCO | 48 | 120 | 84 | 80 | 131 | 500 | 280 |

| PCO-410-8 | PCO | 48 | 120 | 96 | 80 | 131 | 500 | 320 |

| PCO-412-6 | PCO | 48 | 144 | 72 | 80 | 155 | 500 | 288 |

| PCO-412-7 | PCO | 48 | 144 | 84 | 81 | 155 | 500 | 336 |

| PCO-412-8 | PCO | 48 | 144 | 96 | 82 | 155 | 500 | 384 |

| PCO-414-6 | PCO | 48 | 168 | 72 | 81 | 179 | 500 | 336 |

| PCO-414-7 | PCO | 48 | 168 | 84 | 82 | 179 | 500 | 392 |

| PCO-414-8 | PCO | 48 | 168 | 96 | 82 | 179 | 500 | 448 |

| PCO-416-6 | PCO | 48 | 192 | 72 | 82 | 203 | 500 | 384 |

| PCO-416-7 | PCO | 48 | 192 | 84 | 82 | 203 | 500 | 448 |

| PCO-416-8 | PCO | 48 | 192 | 96 | 83 | 203 | 500 | 512 |

| PCO-506-6 | PCO | 60 | 72 | 72 | 92 | 83 | 500 | 180 |

| PCO-506-7 | PCO | 60 | 72 | 84 | 92 | 83 | 500 | 210 |

| PCO-506-8 | PCO | 60 | 72 | 96 | 92 | 83 | 500 | 240 |

| PCO-508-6 | PCO | 60 | 96 | 72 | 92 | 107 | 500 | 240 |

| PCO-508-7 | PCO | 60 | 96 | 84 | 92 | 107 | 500 | 280 |

| PCO-508-8 | PCO | 60 | 96 | 96 | 92 | 107 | 500 | 320 |

| PCO-510-6 | PCO | 60 | 120 | 72 | 92 | 131 | 500 | 300 |

| PCO-510-7 | PCO | 60 | 120 | 84 | 93 | 131 | 500 | 350 |

| PCO-510-8 | PCO | 60 | 120 | 96 | 94 | 131 | 500 | 400 |

| PCO-512-6 | PCO | 60 | 144 | 72 | 93 | 155 | 500 | 360 |

| PCO-512-7 | PCO | 60 | 144 | 84 | 95 | 155 | 500 | 420 |

| PCO-512-8 | PCO | 60 | 144 | 96 | 94 | 155 | 500 | 480 |

| PCO-514-6 | PCO | 60 | 168 | 72 | 95 | 179 | 500 | 420 |

| PCO-514-7 | PCO | 60 | 168 | 84 | 95 | 179 | 500 | 490 |

| PCO-514-8 | PCO | 60 | 168 | 96 | 96 | 179 | 500 | 560 |

| PCO-516-6 | PCO | 60 | 192 | 72 | 94 | 203 | 500 | 480 |

| PCO-516-7 | PCO | 60 | 192 | 84 | 96 | 203 | 500 | 560 |

| PCO-516-8 | PCO | 60 | 192 | 96 | 98 | 203 | 500 | 640 |

| PCO-606-6 | PCO | 72 | 72 | 72 | 104 | 83 | 500 | 216 |

| PCO-606-7 | PCO | 72 | 72 | 84 | 104 | 83 | 500 | 252 |

| PCO-606-8 | PCO | 72 | 72 | 96 | 104 | 83 | 500 | 288 |

| PCO-608-6 | PCO | 72 | 96 | 72 | 104 | 107 | 500 | 288 |

| PCO-608-7 | PCO | 72 | 96 | 84 | 105 | 107 | 500 | 336 |

| PCO-608-8 | PCO | 72 | 96 | 96 | 106 | 107 | 500 | 384 |

| PCO-610-6 | PCO | 72 | 120 | 72 | 106 | 131 | 500 | 360 |

| PCO-610-7 | PCO | 72 | 120 | 84 | 107 | 131 | 500 | 420 |

| PCO-610-8 | PCO | 72 | 120 | 96 | 106 | 131 | 500 | 480 |

| PCO-612-6 | PCO | 72 | 144 | 72 | 106 | 155 | 500 | 432 |

| PCO-612-7 | PCO | 72 | 144 | 84 | 107 | 155 | 500 | 504 |

| PCO-612-8 | PCO | 72 | 144 | 96 | 108 | 155 | 500 | 576 |

| PCO-614-6 | PCO | 72 | 168 | 72 | 107 | 179 | 500 | 504 |

| PCO-614-7 | PCO | 72 | 168 | 84 | 109 | 179 | 500 | 588 |

| PCO-614-8 | PCO | 72 | 168 | 96 | 109 | 179 | 500 | 672 |

| PCO-616-6 | PCO | 72 | 192 | 72 | 108 | 203 | 500 | 576 |

| PCO-616-7 | PCO | 72 | 192 | 84 | 109 | 203 | 500 | 672 |

| PCO-616-8 | PCO | 72 | 192 | 96 | 111 | 203 | 500 | 768 |

| PCO-706-6 | PCO | 84 | 72 | 72 | 116 | 83 | 500 | 252 |

| PCO-706-7 | PCO | 84 | 72 | 84 | 116 | 83 | 500 | 294 |

| PCO-706-8 | PCO | 84 | 72 | 96 | 117 | 83 | 500 | 336 |

| PCO-708-6 | PCO | 84 | 96 | 72 | 117 | 107 | 500 | 336 |

| PCO-708-7 | PCO | 84 | 96 | 84 | 118 | 107 | 500 | 392 |

| PCO-708-8 | PCO | 84 | 96 | 96 | 118 | 107 | 500 | 448 |

| PCO-710-6 | PCO | 84 | 120 | 72 | 119 | 131 | 500 | 420 |

| PCO-710-7 | PCO | 84 | 120 | 84 | 119 | 131 | 500 | 490 |

| PCO-710-8 | PCO | 84 | 120 | 96 | 120 | 131 | 500 | 560 |

| PCO-712-6 | PCO | 84 | 144 | 72 | 119 | 155 | 500 | 504 |

| PCO-712-7 | PCO | 84 | 144 | 84 | 121 | 155 | 500 | 588 |

| PCO-712-8 | PCO | 84 | 144 | 96 | 121 | 155 | 500 | 672 |

| PCO-714-6 | PCO | 84 | 168 | 72 | 121 | 179 | 500 | 588 |

| PCO-714-7 | PCO | 84 | 168 | 84 | 121 | 179 | 500 | 686 |

| PCO-714-8 | PCO | 84 | 168 | 96 | 123 | 179 | 500 | 784 |

| PCO-716-6 | PCO | 84 | 192 | 72 | 121 | 203 | 500 | 672 |

| PCO-716-7 | PCO | 84 | 192 | 84 | 123 | 203 | 500 | 784 |

| PCO-716-8 | PCO | 84 | 192 | 96 | 124 | 203 | 500 | 896 |

| PCO-806-6 | PCO | 96 | 72 | 72 | 128 | 83 | 500 | 288 |

| PCO-806-7 | PCO | 96 | 72 | 84 | 129 | 83 | 500 | 336 |

| PCO-806-8 | PCO | 96 | 72 | 96 | 130 | 83 | 500 | 384 |

| PCO-808-6 | PCO | 96 | 96 | 72 | 130 | 107 | 500 | 384 |

| PCO-808-7 | PCO | 96 | 96 | 84 | 130 | 107 | 500 | 448 |

| PCO-808-8 | PCO | 96 | 96 | 96 | 131 | 107 | 500 | 512 |

| PCO-810-6 | PCO | 96 | 120 | 72 | 130 | 131 | 500 | 480 |

| PCO-810-7 | PCO | 96 | 120 | 84 | 132 | 131 | 500 | 560 |

| PCO-810-8 | PCO | 96 | 120 | 96 | 134 | 131 | 500 | 640 |

| PCO-812-6 | PCO | 96 | 144 | 72 | 132 | 155 | 500 | 576 |

| PCO-812-7 | PCO | 96 | 144 | 84 | 133 | 155 | 500 | 672 |

| PCO-812-8 | PCO | 96 | 144 | 96 | 135 | 155 | 500 | 768 |

| PCO-814-6 | PCO | 96 | 168 | 72 | 133 | 179 | 500 | 672 |

| PCO-814-7 | PCO | 96 | 168 | 84 | 135 | 179 | 500 | 784 |

| PCO-814-8 | PCO | 96 | 168 | 96 | 136 | 179 | 500 | 896 |

| PCO-816-6 | PCO | 96 | 192 | 72 | 135 | 203 | 500 | 768 |

| PCO-816-7 | PCO | 96 | 192 | 84 | 136 | 203 | 500 | 896 |

| PCO-816-8 | PCO | 96 | 192 | 96 | 137 | 203 | 500 | 1024 |

| 73-500 | TR | 36 | 36 | 60 | 70 | 48 | 500 | 45 |

| 73-800 | TR | 36 | 36 | 60 | 79 | 52 | 800 | 45 |

| 74-500 | TR | 48 | 48 | 60 | 82 | 58 | 500 | 80 |

| 74-800 | TR | 48 | 48 | 60 | 91 | 62 | 800 | 80 |

| 75-500 | TR | 60 | 60 | 60 | 96 | 70 | 500 | 125 |

| 75-800 | TR | 60 | 60 | 60 | 103 | 74 | 800 | 125 |

| 76-500 | TR | 72 | 72 | 60 | 96 | 70 | 500 | 180 |

| 76-800 | TR | 72 | 72 | 60 | 115 | 84 | 800 | 180 |

| X2-3-202020 | X2 | 20 | 20 | 20 | 54 | 36 | 350 | 4.63 |

| X2-3-262626 | X2 | 26 | 26 | 26 | 60 | 42 | 350 | 10.17 |

| X2-3-262638 | X2 | 26 | 26 | 38 | 60 | 42 | 350 | 14.87 |

| X2-3-382638 | X2 | 38 | 26 | 38 | 72 | 42 | 350 | 21.73 |

| X2-3-383838 | X2 | 38 | 38 | 38 | 72 | 54 | 350 | 31.75 |

| X2-3-503850 | X2 | 50 | 38 | 50 | 84 | 54 | 350 | 54.98 |

| X2-3-505038 | X2 | 50 | 50 | 38 | 75 | 66 | 350 | 54.98 |

| X2-3-505050 | X2 | 50 | 50 | 50 | 94 | 66 | 350 | 72.34 |

| X2-5-202020 | X2 | 20 | 20 | 20 | 54 | 36 | 500 | 4.63 |

| X2-5-262626 | X2 | 26 | 26 | 26 | 60 | 42 | 500 | 10.17 |

| X2-5-262638 | X2 | 26 | 26 | 38 | 60 | 42 | 500 | 14.87 |

| X2-5-382638 | X2 | 38 | 26 | 38 | 72 | 42 | 500 | 21.73 |

| X2-5-383838 | X2 | 38 | 38 | 38 | 72 | 54 | 500 | 31.75 |

| X2-5-503850 | X2 | 50 | 38 | 50 | 84 | 54 | 500 | 54.98 |

| X2-5-505038 | X2 | 50 | 50 | 38 | 75 | 66 | 500 | 54.98 |

| X2-5-505050 | X2 | 50 | 50 | 50 | 94 | 66 | 500 | 72.34 |

| X2-6-202020 | X2 | 20 | 20 | 20 | 54 | 36 | 600 | 4.63 |

| X2-6-262626 | X2 | 26 | 26 | 26 | 60 | 42 | 600 | 10.17 |

| X2-6-262638 | X2 | 26 | 26 | 38 | 60 | 42 | 600 | 14.87 |

| X2-6-382638 | X2 | 38 | 26 | 38 | 72 | 42 | 600 | 21.73 |

| X2-6-383838 | X2 | 38 | 38 | 38 | 72 | 54 | 600 | 31.75 |

| X2-6-503850 | X2 | 50 | 38 | 50 | 84 | 54 | 600 | 54.98 |

| X2-6-505038 | X2 | 50 | 50 | 38 | 75 | 66 | 600 | 54.98 |

| X2-6-505050 | X2 | 50 | 50 | 50 | 94 | 66 | 600 | 72.34 |

| X2-8-202020 | X2 | 20 | 20 | 20 | 54 | 36 | 800 | 4.63 |

| X2-8-262626 | X2 | 26 | 26 | 26 | 60 | 42 | 800 | 10.17 |

| X2-8-262638 | X2 | 26 | 26 | 38 | 60 | 42 | 800 | 14.87 |

| X2-8-382638 | X2 | 38 | 26 | 38 | 72 | 42 | 800 | 21.73 |

| X2-8-383838 | X2 | 38 | 38 | 38 | 72 | 54 | 800 | 31.75 |

| X2-8-503850 | X2 | 50 | 38 | 50 | 84 | 54 | 800 | 54.98 |

| X2-8-505038 | X2 | 50 | 50 | 38 | 75 | 66 | 800 | 54.98 |

| X2-8-505050 | X2 | 50 | 50 | 50 | 94 | 66 | 800 | 72.34 |

| X2-10-202020 | X2HT | 20 | 20 | 20 | 55 | 39 | 1000 | 4.63 |

| X2-10-262626 | X2HT | 26 | 26 | 26 | 62 | 45 | 1000 | 10.17 |

| X2-10-262638 | X2HT | 26 | 26 | 38 | 62 | 45 | 1000 | 14.87 |

| X2-10-382638 | X2HT | 38 | 26 | 38 | 74 | 45 | 1000 | 21.73 |

| X2-10-383838 | X2HT | 38 | 38 | 38 | 74 | 57 | 1000 | 31.75 |

| X2-10-503850 | X2HT | 50 | 38 | 50 | 86 | 57 | 1000 | 54.98 |

| X2-10-505038 | X2HT | 50 | 50 | 38 | 86 | 69 | 1000 | 54.98 |

| X2-10-505050 | X2HT | 50 | 50 | 50 | 92 | 69 | 1000 | 72.34 |

| X2-12-202020 | X2HT | 20 | 20 | 20 | 61 | 45 | 1200 | 4.63 |

| X2-12-262626 | X2HT | 26 | 26 | 26 | 75 | 58 | 1200 | 10.17 |

| X2-12-262638 | X2HT | 26 | 26 | 38 | 75 | 51 | 1200 | 14.87 |

| X2-12-382638 | X2HT | 38 | 26 | 38 | 80 | 51 | 1200 | 21.73 |

| X2-12-383838 | X2HT | 38 | 38 | 38 | 80 | 63 | 1200 | 31.75 |

| X2-12-503850 | X2HT | 50 | 38 | 50 | 92 | 63 | 1200 | 54.98 |

| X2-12-505038 | X2HT | 50 | 50 | 38 | 92 | 75 | 1200 | 54.98 |

| X2-12-505050 | X2HT | 50 | 50 | 50 | 98 | 75 | 1200 | 72.34 |

| HD4T-404-6 | HD4T | 48 | 48 | 72 | 500 | 96 | ||

| HD4T-404-7 | HD4T | 48 | 48 | 84 | 500 | 112 | ||

| HD4T-404-8 | HD4T | 48 | 48 | 96 | 500 | 128 | ||

| HD4T-406-6 | HD4T | 48 | 72 | 72 | 500 | 144 | ||

| HD4T-406-7 | HD4T | 48 | 72 | 84 | 500 | 168 | ||

| HD4T-406-8 | HD4T | 48 | 72 | 96 | 500 | 192 | ||

| HD4T-408-6 | HD4T | 48 | 96 | 72 | 500 | 192 | ||

| HD4T-408-7 | HD4T | 48 | 96 | 84 | 500 | 224 | ||

| HD4T-408-8 | HD4T | 48 | 96 | 96 | 500 | 256 | ||

| HD4T-410-6 | HD4T | 48 | 120 | 72 | 500 | 240 | ||

| HD4T-410-7 | HD4T | 48 | 120 | 84 | 500 | 280 | ||

| HD4T-410-8 | HD4T | 48 | 120 | 96 | 500 | 320 | ||

| HD4T-412-6 | HD4T | 48 | 144 | 72 | 500 | 288 | ||

| HD4T-412-7 | HD4T | 48 | 144 | 84 | 500 | 336 | ||

| HD4T-412-8 | HD4T | 48 | 144 | 96 | 500 | 384 | ||

| HD4T-414-6 | HD4T | 48 | 168 | 72 | 500 | 336 | ||

| HD4T-414-7 | HD4T | 48 | 168 | 84 | 500 | 392 | ||

| HD4T-414-8 | HD4T | 48 | 168 | 96 | 500 | 448 | ||

| HD4T-416-6 | HD4T | 48 | 192 | 72 | 500 | 384 | ||

| HD4T-416-7 | HD4T | 48 | 192 | 84 | 500 | 448 | ||

| HD4T-416-8 | HD4T | 48 | 192 | 96 | 500 | 512 | ||

| HD4T-504-6 | HD4T | 60 | 48 | 72 | 500 | 120 | ||

| HD4T-504-7 | HD4T | 60 | 48 | 84 | 500 | 140 | ||

| HD4T-504-8 | HD4T | 60 | 48 | 96 | 500 | 160 | ||

| HD4T-506-6 | HD4T | 60 | 72 | 72 | 500 | 180 | ||

| HD4T-506-7 | HD4T | 60 | 72 | 84 | 500 | 210 | ||

| HD4T-506-8 | HD4T | 60 | 72 | 96 | 500 | 240 | ||

| HD4T-508-6 | HD4T | 60 | 96 | 72 | 500 | 240 | ||

| HD4T-508-7 | HD4T | 60 | 96 | 84 | 500 | 280 | ||

| HD4T-508-8 | HD4T | 60 | 96 | 96 | 500 | 320 | ||

| HD4T-510-6 | HD4T | 60 | 120 | 72 | 500 | 300 | ||

| HD4T-510-7 | HD4T | 60 | 120 | 84 | 500 | 350 | ||

| HD4T-510-8 | HD4T | 60 | 120 | 96 | 500 | 400 | ||

| HD4T-512-6 | HD4T | 60 | 144 | 72 | 500 | 360 | ||

| HD4T-512-7 | HD4T | 60 | 144 | 84 | 500 | 420 | ||

| HD4T-512-8 | HD4T | 60 | 144 | 96 | 500 | 480 | ||

| HD4T-514-6 | HD4T | 60 | 168 | 72 | 500 | 420 | ||

| HD4T-514-7 | HD4T | 60 | 168 | 84 | 500 | 490 | ||

| HD4T-514-8 | HD4T | 60 | 168 | 96 | 500 | 560 | ||

| HD4T-516-6 | HD4T | 60 | 192 | 72 | 500 | 480 | ||

| HD4T-516-7 | HD4T | 60 | 192 | 84 | 500 | 560 | ||

| HD4T-516-8 | HD4T | 60 | 192 | 96 | 500 | 640 | ||

| HD4T-604-6 | HD4T | 72 | 48 | 72 | 500 | 144 | ||

| HD4T-604-7 | HD4T | 72 | 48 | 84 | 500 | 168 | ||

| HD4T-604-8 | HD4T | 72 | 48 | 96 | 500 | 192 | ||

| HD4T-606-6 | HD4T | 72 | 72 | 72 | 500 | 216 | ||

| HD4T-606-7 | HD4T | 72 | 72 | 84 | 500 | 252 | ||

| HD4T-606-8 | HD4T | 72 | 72 | 96 | 500 | 288 | ||

| HD4T-608-6 | HD4T | 72 | 96 | 72 | 500 | 288 | ||

| HD4T-608-7 | HD4T | 72 | 96 | 84 | 500 | 336 | ||

| HD4T-608-8 | HD4T | 72 | 96 | 96 | 500 | 384 | ||

| HD4T-610-6 | HD4T | 72 | 120 | 72 | 500 | 360 | ||

| HD4T-610-7 | HD4T | 72 | 120 | 84 | 500 | 420 | ||

| HD4T-610-8 | HD4T | 72 | 120 | 96 | 500 | 480 | ||

| HD4T-612-6 | HD4T | 72 | 144 | 72 | 500 | 432 | ||

| HD4T-612-7 | HD4T | 72 | 144 | 84 | 500 | 504 | ||

| HD4T-612-8 | HD4T | 72 | 144 | 96 | 500 | 576 | ||

| HD4T-614-6 | HD4T | 72 | 168 | 72 | 500 | 504 | ||

| HD4T-614-7 | HD4T | 72 | 168 | 84 | 500 | 588 | ||

| HD4T-614-8 | HD4T | 72 | 168 | 96 | 500 | 672 | ||

| HD4T-616-6 | HD4T | 72 | 192 | 72 | 500 | 576 | ||

| HD4T-616-7 | HD4T | 72 | 192 | 84 | 500 | 672 | ||

| HD4T-616-8 | HD4T | 72 | 192 | 96 | 500 | 768 | ||

| HD4T-704-6 | HD4T | 84 | 48 | 72 | 500 | 168 | ||

| HD4T-704-7 | HD4T | 84 | 48 | 84 | 500 | 196 | ||

| HD4T-704-8 | HD4T | 84 | 48 | 96 | 500 | 224 | ||

| HD4T-706-6 | HD4T | 84 | 72 | 72 | 500 | 252 | ||

| HD4T-706-7 | HD4T | 84 | 72 | 84 | 500 | 294 | ||

| HD4T-706-8 | HD4T | 84 | 72 | 96 | 500 | 336 | ||

| HD4T-708-6 | HD4T | 84 | 96 | 72 | 500 | 336 | ||

| HD4T-708-7 | HD4T | 84 | 96 | 84 | 500 | 392 | ||

| HD4T-708-8 | HD4T | 84 | 96 | 96 | 500 | 448 | ||

| HD4T-710-6 | HD4T | 84 | 120 | 72 | 500 | 420 | ||

| HD4T-710-7 | HD4T | 84 | 120 | 84 | 500 | 490 | ||

| HD4T-710-8 | HD4T | 84 | 120 | 96 | 500 | 560 | ||

| HD4T-712-6 | HD4T | 84 | 144 | 72 | 500 | 504 | ||

| HD4T-712-7 | HD4T | 84 | 144 | 84 | 500 | 588 | ||

| HD4T-712-8 | HD4T | 84 | 144 | 96 | 500 | 672 | ||

| HD4T-714-6 | HD4T | 84 | 168 | 72 | 500 | 588 | ||

| HD4T-714-7 | HD4T | 84 | 168 | 84 | 500 | 686 | ||

| HD4T-714-8 | HD4T | 84 | 168 | 96 | 500 | 784 | ||

| HD4T-716-6 | HD4T | 84 | 192 | 72 | 500 | 672 | ||

| HD4T-716-7 | HD4T | 84 | 192 | 84 | 500 | 784 | ||

| HD4T-716-8 | HD4T | 84 | 192 | 96 | 500 | 896 | ||

| HD4T-804-6 | HD4T | 96 | 48 | 72 | 500 | 192 | ||

| HD4T-804-7 | HD4T | 96 | 48 | 84 | 500 | 224 | ||

| HD4T-804-8 | HD4T | 96 | 48 | 96 | 500 | 256 | ||

| HD4T-806-6 | HD4T | 96 | 72 | 72 | 500 | 288 | ||

| HD4T-806-7 | HD4T | 96 | 72 | 84 | 500 | 336 | ||

| HD4T-806-8 | HD4T | 96 | 72 | 96 | 500 | 384 | ||

| HD4T-808-6 | HD4T | 96 | 96 | 72 | 500 | 384 | ||

| HD4T-808-7 | HD4T | 96 | 96 | 84 | 500 | 448 | ||

| HD4T-808-8 | HD4T | 96 | 96 | 96 | 500 | 512 | ||

| HD4T-810-6 | HD4T | 96 | 120 | 72 | 500 | 480 | ||

| HD4T-810-7 | HD4T | 96 | 120 | 84 | 500 | 560 | ||

| HD4T-810-8 | HD4T | 96 | 120 | 96 | 500 | 640 | ||

| HD4T-812-6 | HD4T | 96 | 144 | 72 | 500 | 576 | ||

| HD4T-812-7 | HD4T | 96 | 144 | 84 | 500 | 672 | ||

| HD4T-812-8 | HD4T | 96 | 144 | 96 | 500 | 768 | ||

| HD4T-814-6 | HD4T | 96 | 168 | 72 | 500 | 672 | ||

| HD4T-814-7 | HD4T | 96 | 168 | 84 | 500 | 784 | ||

| HD4T-814-8 | HD4T | 96 | 168 | 96 | 500 | 896 | ||

| HD4T-816-6 | HD4T | 96 | 192 | 72 | 500 | 768 | ||

| HD4T-816-7 | HD4T | 96 | 192 | 84 | 500 | 896 | ||

| HD4T-816-8 | HD4T | 96 | 192 | 96 | 500 | 1024 | ||

| HD4B-404-6 | HD4B | 48 | 48 | 72 | 80 | 111 | 500 | 96 |

| HD4B-404-7 | HD4B | 48 | 48 | 84 | 80 | 111 | 500 | 112 |

| HD4B-404-8 | HD4B | 48 | 48 | 96 | 80 | 111 | 500 | 128 |

| HD4B-406-6 | HD4B | 48 | 72 | 72 | 80 | 135 | 500 | 144 |

| HD4B-406-7 | HD4B | 48 | 72 | 84 | 80 | 135 | 500 | 168 |

| HD4B-406-8 | HD4B | 48 | 72 | 96 | 80 | 135 | 500 | 192 |

| HD4B-408-6 | HD4B | 48 | 96 | 72 | 80 | 159 | 500 | 192 |

| HD4B-408-7 | HD4B | 48 | 96 | 84 | 80 | 159 | 500 | 224 |

| HD4B-408-8 | HD4B | 48 | 96 | 96 | 80 | 163 | 500 | 256 |

| HD4B-410-6 | HD4B | 48 | 120 | 72 | 80 | 183 | 500 | 240 |

| HD4B-410-7 | HD4B | 48 | 120 | 84 | 84 | 187 | 500 | 280 |

| HD4B-410-8 | HD4B | 48 | 120 | 96 | 84 | 187 | 500 | 320 |

| HD4B-412-6 | HD4B | 48 | 144 | 72 | 80 | 211 | 500 | 288 |

| HD4B-412-7 | HD4B | 48 | 144 | 84 | 84 | 211 | 500 | 336 |

| HD4B-412-8 | HD4B | 48 | 144 | 96 | 84 | 211 | 500 | 384 |

| HD4B-414-6 | HD4B | 48 | 168 | 72 | 84 | 235 | 500 | 336 |

| HD4B-414-7 | HD4B | 48 | 168 | 84 | 84 | 235 | 500 | 392 |

| HD4B-414-8 | HD4B | 48 | 168 | 96 | 84 | 235 | 500 | 448 |

| HD4B-416-6 | HD4B | 48 | 192 | 72 | 84 | 259 | 500 | 384 |

| HD4B-416-7 | HD4B | 48 | 192 | 84 | 84 | 259 | 500 | 448 |

| HD4B-416-8 | HD4B | 48 | 192 | 96 | 84 | 259 | 500 | 512 |

| HD4B-504-6 | HD4B | 60 | 48 | 72 | 92 | 111 | 500 | 120 |

| HD4B-504-7 | HD4B | 60 | 48 | 84 | 92 | 111 | 500 | 140 |

| HD4B-504-8 | HD4B | 60 | 48 | 96 | 92 | 111 | 500 | 160 |

| HD4B-506-6 | HD4B | 60 | 72 | 72 | 92 | 135 | 500 | 180 |

| HD4B-506-7 | HD4B | 60 | 72 | 84 | 92 | 135 | 500 | 210 |

| HD4B-506-8 | HD4B | 60 | 72 | 96 | 92 | 135 | 500 | 240 |

| HD4B-508-6 | HD4B | 60 | 96 | 72 | 92 | 159 | 500 | 240 |

| HD4B-508-7 | HD4B | 60 | 96 | 84 | 96 | 163 | 500 | 280 |

| HD4B-508-8 | HD4B | 60 | 96 | 96 | 96 | 163 | 500 | 320 |

| HD4B-510-6 | HD4B | 60 | 120 | 72 | 96 | 187 | 500 | 300 |

| HD4B-510-7 | HD4B | 60 | 120 | 84 | 96 | 187 | 500 | 350 |

| HD4B-510-8 | HD4B | 60 | 120 | 96 | 96 | 187 | 500 | 400 |

| HD4B-512-6 | HD4B | 60 | 144 | 72 | 96 | 211 | 500 | 360 |

| HD4B-512-7 | HD4B | 60 | 144 | 84 | 96 | 211 | 500 | 420 |

| HD4B-512-8 | HD4B | 60 | 144 | 96 | 96 | 211 | 500 | 480 |

| HD4B-514-6 | HD4B | 60 | 168 | 72 | 96 | 235 | 500 | 420 |

| HD4B-514-7 | HD4B | 60 | 168 | 84 | 96 | 235 | 500 | 490 |

| HD4B-514-8 | HD4B | 60 | 168 | 96 | 100 | 235 | 500 | 560 |

| HD4B-516-6 | HD4B | 60 | 192 | 72 | 96 | 259 | 500 | 480 |

| HD4B-516-7 | HD4B | 60 | 192 | 84 | 100 | 259 | 500 | 560 |

| HD4B-516-8 | HD4B | 60 | 192 | 96 | 96 | 263 | 500 | 640 |

| HD4B-604-6 | HD4B | 72 | 48 | 72 | 104 | 111 | 500 | 144 |

| HD4B-604-7 | HD4B | 72 | 48 | 84 | 104 | 111 | 500 | 168 |

| HD4B-604-8 | HD4B | 72 | 48 | 96 | 104 | 111 | 500 | 192 |

| HD4B-606-6 | HD4B | 72 | 72 | 72 | 104 | 135 | 500 | 216 |

| HD4B-606-7 | HD4B | 72 | 72 | 84 | 104 | 135 | 500 | 252 |

| HD4B-606-8 | HD4B | 72 | 72 | 96 | 108 | 139 | 500 | 288 |

| HD4B-608-6 | HD4B | 72 | 96 | 72 | 108 | 163 | 500 | 288 |

| HD4B-608-7 | HD4B | 72 | 96 | 84 | 108 | 163 | 500 | 336 |

| HD4B-608-8 | HD4B | 72 | 96 | 96 | 108 | 163 | 500 | 384 |

| HD4B-610-6 | HD4B | 72 | 120 | 72 | 108 | 187 | 500 | 360 |

| HD4B-610-7 | HD4B | 72 | 120 | 84 | 108 | 187 | 500 | 420 |

| HD4B-610-8 | HD4B | 72 | 120 | 96 | 108 | 187 | 500 | 480 |

| HD4B-612-6 | HD4B | 72 | 144 | 72 | 108 | 211 | 500 | 432 |

| HD4B-612-7 | HD4B | 72 | 144 | 84 | 108 | 211 | 500 | 504 |

| HD4B-612-8 | HD4B | 72 | 144 | 96 | 108 | 211 | 500 | 576 |

| HD4B-614-6 | HD4B | 72 | 168 | 72 | 108 | 235 | 500 | 504 |

| HD4B-614-7 | HD4B | 72 | 168 | 84 | 112 | 239 | 500 | 588 |

| HD4B-614-8 | HD4B | 72 | 168 | 96 | 108 | 239 | 500 | 672 |

| HD4B-616-6 | HD4B | 72 | 192 | 72 | 112 | 259 | 500 | 576 |

| HD4B-616-7 | HD4B | 72 | 192 | 84 | 108 | 263 | 500 | 672 |

| HD4B-616-8 | HD4B | 72 | 192 | 96 | 112 | 266 | 500 | 768 |

| HD4B-704-6 | HD4B | 84 | 48 | 72 | 116 | 111 | 500 | 168 |

| HD4B-704-7 | HD4B | 84 | 48 | 84 | 116 | 111 | 500 | 196 |

| HD4B-704-8 | HD4B | 84 | 48 | 96 | 116 | 111 | 500 | 224 |

| HD4B-706-6 | HD4B | 84 | 72 | 72 | 116 | 135 | 500 | 252 |

| HD4B-706-7 | HD4B | 84 | 72 | 84 | 116 | 139 | 500 | 294 |

| HD4B-706-8 | HD4B | 84 | 72 | 96 | 120 | 139 | 500 | 336 |

| HD4B-708-6 | HD4B | 84 | 96 | 72 | 120 | 163 | 500 | 336 |

| HD4B-708-7 | HD4B | 84 | 96 | 84 | 120 | 163 | 500 | 392 |

| HD4B-708-8 | HD4B | 84 | 96 | 96 | 120 | 163 | 500 | 448 |

| HD4B-710-6 | HD4B | 84 | 120 | 72 | 120 | 187 | 500 | 420 |

| HD4B-710-7 | HD4B | 84 | 120 | 84 | 120 | 187 | 500 | 490 |

| HD4B-710-8 | HD4B | 84 | 120 | 96 | 124 | 187 | 500 | 560 |

| HD4B-712-6 | HD4B | 84 | 144 | 72 | 120 | 211 | 500 | 504 |

| HD4B-712-7 | HD4B | 84 | 144 | 84 | 120 | 215 | 500 | 588 |

| HD4B-712-8 | HD4B | 84 | 144 | 96 | 120 | 215 | 500 | 672 |

| HD4B-714-6 | HD4B | 84 | 168 | 72 | 124 | 239 | 500 | 588 |

| HD4B-714-7 | HD4B | 84 | 168 | 84 | 120 | 239 | 500 | 686 |

| HD4B-714-8 | HD4B | 84 | 168 | 96 | 124 | 242 | 500 | 784 |

| HD4B-716-6 | HD4B | 84 | 192 | 72 | 120 | 263 | 500 | 672 |

| HD4B-716-7 | HD4B | 84 | 192 | 84 | 124 | 266 | 500 | 784 |

| HD4B-716-8 | HD4B | 84 | 192 | 96 | 128 | 266 | 500 | 896 |

| HD4B-804-6 | HD4B | 96 | 48 | 72 | 128 | 111 | 500 | 192 |

| HD4B-804-7 | HD4B | 96 | 48 | 84 | 128 | 111 | 500 | 224 |

| HD4B-804-8 | HD4B | 96 | 48 | 96 | 128 | 115 | 500 | 256 |

| HD4B-806-6 | HD4B | 96 | 72 | 72 | 132 | 139 | 500 | 288 |

| HD4B-806-7 | HD4B | 96 | 72 | 84 | 132 | 139 | 500 | 336 |

| HD4B-806-8 | HD4B | 96 | 72 | 96 | 132 | 139 | 500 | 384 |

| HD4B-808-6 | HD4B | 96 | 96 | 72 | 136 | 163 | 500 | 384 |

| HD4B-808-7 | HD4B | 96 | 96 | 84 | 132 | 163 | 500 | 448 |

| HD4B-808-8 | HD4B | 96 | 96 | 96 | 132 | 163 | 500 | 512 |

| HD4B-810-6 | HD4B | 96 | 120 | 72 | 132 | 187 | 500 | 480 |

| HD4B-810-7 | HD4B | 96 | 120 | 84 | 136 | 187 | 500 | 560 |

| HD4B-810-8 | HD4B | 96 | 120 | 96 | 132 | 191 | 500 | 640 |

| HD4B-812-6 | HD4B | 96 | 144 | 72 | 136 | 211 | 500 | 576 |

| HD4B-812-7 | HD4B | 96 | 144 | 84 | 132 | 215 | 500 | 672 |

| HD4B-812-8 | HD4B | 96 | 144 | 96 | 136 | 218 | 500 | 768 |

| HD4B-814-6 | HD4B | 96 | 168 | 72 | 136 | 239 | 500 | 672 |

| HD4B-814-7 | HD4B | 96 | 168 | 84 | 136 | 242 | 500 | 784 |

| HD4B-814-8 | HD4B | 96 | 168 | 96 | 136 | 242 | 500 | 896 |

| HD4B-816-6 | HD4B | 96 | 192 | 72 | 136 | 266 | 500 | 768 |

| HD4B-816-7 | HD4B | 96 | 192 | 84 | 140 | 266 | 500 | 896 |

| HD4B-816-8 | HD4B | 96 | 192 | 96 | 140 | 266 | 500 | 1024 |

| EC-404-6 | EC | 48 | 48 | 72 | 76 | 115 | 500 | 96 |

| EC-404-7 | EC | 48 | 48 | 84 | 76 | 115 | 500 | 112 |

| EC-404-8 | EC | 48 | 48 | 96 | 76 | 115 | 500 | 128 |

| EC-406-6 | EC | 48 | 72 | 72 | 79 | 139 | 500 | 144 |

| EC-406-7 | EC | 48 | 72 | 84 | 79 | 139 | 500 | 168 |

| EC-406-8 | EC | 48 | 72 | 96 | 79 | 139 | 500 | 192 |

| EC-408-6 | EC | 48 | 96 | 72 | 79 | 163 | 500 | 192 |

| EC-408-7 | EC | 48 | 96 | 84 | 79 | 163 | 500 | 224 |

| EC-408-8 | EC | 48 | 96 | 96 | 79 | 163 | 500 | 256 |

| EC-410-6 | EC | 48 | 120 | 72 | 82 | 187 | 500 | 240 |

| EC-410-7 | EC | 48 | 120 | 84 | 82 | 187 | 500 | 280 |

| EC-410-8 | EC | 48 | 120 | 96 | 82 | 187 | 500 | 320 |

| EC-412-6 | EC | 48 | 144 | 72 | 82 | 211 | 500 | 288 |

| EC-412-7 | EC | 48 | 144 | 84 | 82 | 215 | 500 | 336 |

| EC-412-8 | EC | 48 | 144 | 96 | 82 | 215 | 500 | 384 |

| EC-414-6 | EC | 48 | 168 | 72 | 85 | 239 | 500 | 336 |

| EC-414-7 | EC | 48 | 168 | 84 | 85 | 239 | 500 | 392 |

| EC-414-8 | EC | 48 | 168 | 96 | 85 | 239 | 500 | 448 |

| EC-416-6 | EC | 48 | 192 | 72 | 85 | 263 | 500 | 384 |

| EC-416-7 | EC | 48 | 192 | 84 | 85 | 263 | 500 | 448 |

| EC-416-8 | EC | 48 | 192 | 96 | 85 | 263 | 500 | 512 |

| EC-504-6 | EC | 60 | 48 | 72 | 88 | 115 | 500 | 120 |

| EC-504-7 | EC | 60 | 48 | 84 | 88 | 115 | 500 | 140 |

| EC-504-8 | EC | 60 | 48 | 96 | 88 | 115 | 500 | 160 |

| EC-506-6 | EC | 60 | 72 | 72 | 91 | 139 | 500 | 180 |

| EC-506-7 | EC | 60 | 72 | 84 | 91 | 139 | 500 | 210 |

| EC-506-8 | EC | 60 | 72 | 96 | 91 | 139 | 500 | 240 |

| EC-508-6 | EC | 60 | 96 | 72 | 91 | 163 | 500 | 240 |

| EC-508-7 | EC | 60 | 96 | 84 | 91 | 163 | 500 | 280 |

| EC-508-8 | EC | 60 | 96 | 96 | 91 | 163 | 500 | 320 |

| EC-510-6 | EC | 60 | 120 | 72 | 94 | 187 | 500 | 300 |

| EC-510-7 | EC | 60 | 120 | 84 | 94 | 191 | 500 | 350 |

| EC-510-8 | EC | 60 | 120 | 96 | 94 | 191 | 500 | 400 |

| EC-512-6 | EC | 60 | 144 | 72 | 94 | 215 | 500 | 360 |

| EC-512-7 | EC | 60 | 144 | 84 | 94 | 215 | 500 | 420 |

| EC-512-8 | EC | 60 | 144 | 96 | 94 | 215 | 500 | 480 |

| EC-514-6 | EC | 60 | 168 | 72 | 97 | 239 | 500 | 420 |

| EC-514-7 | EC | 60 | 168 | 84 | 97 | 239 | 500 | 490 |

| EC-514-8 | EC | 60 | 168 | 96 | 97 | 239 | 500 | 560 |

| EC-516-6 | EC | 60 | 192 | 72 | 97 | 263 | 500 | 480 |

| EC-516-7 | EC | 60 | 192 | 84 | 97 | 263 | 500 | 560 |

| EC-516-8 | EC | 60 | 192 | 96 | 97 | 263 | 500 | 640 |

| EC-604-6 | EC | 72 | 48 | 72 | 100 | 115 | 500 | 144 |

| EC-604-7 | EC | 72 | 48 | 84 | 100 | 115 | 500 | 168 |

| EC-604-8 | EC | 72 | 48 | 96 | 100 | 115 | 500 | 192 |

| EC-606-6 | EC | 72 | 72 | 72 | 103 | 139 | 500 | 216 |

| EC-606-7 | EC | 72 | 72 | 84 | 103 | 139 | 500 | 252 |

| EC-606-8 | EC | 72 | 72 | 96 | 103 | 139 | 500 | 288 |

| EC-608-6 | EC | 72 | 96 | 72 | 103 | 163 | 500 | 288 |

| EC-608-7 | EC | 72 | 96 | 84 | 103 | 167 | 500 | 336 |

| EC-608-8 | EC | 72 | 96 | 96 | 103 | 167 | 500 | 384 |

| EC-610-6 | EC | 72 | 120 | 72 | 106 | 191 | 500 | 360 |

| EC-610-7 | EC | 72 | 120 | 84 | 106 | 191 | 500 | 420 |

| EC-610-8 | EC | 72 | 120 | 96 | 106 | 191 | 500 | 480 |

| EC-612-6 | EC | 72 | 144 | 72 | 106 | 215 | 500 | 432 |

| EC-612-7 | EC | 72 | 144 | 84 | 106 | 215 | 500 | 504 |

| EC-612-8 | EC | 72 | 144 | 96 | 106 | 215 | 500 | 576 |

| EC-614-6 | EC | 72 | 168 | 72 | 109 | 239 | 500 | 504 |

| EC-614-7 | EC | 72 | 168 | 84 | 109 | 239 | 500 | 588 |

| EC-614-8 | EC | 72 | 168 | 96 | 109 | 239 | 500 | 672 |

| EC-616-6 | EC | 72 | 192 | 72 | 109 | 263 | 500 | 576 |

| EC-616-7 | EC | 72 | 192 | 84 | 109 | 263 | 500 | 672 |

| EC-616-8 | EC | 72 | 192 | 96 | 109 | 263 | 500 | 768 |

| EC-704-6 | EC | 84 | 48 | 72 | 112 | 115 | 500 | 168 |

| EC-704-7 | EC | 84 | 48 | 84 | 112 | 115 | 500 | 196 |

| EC-704-8 | EC | 84 | 48 | 96 | 112 | 115 | 500 | 224 |

| EC-706-6 | EC | 84 | 72 | 72 | 115 | 139 | 500 | 252 |

| EC-706-7 | EC | 84 | 72 | 84 | 115 | 139 | 500 | 294 |

| EC-706-8 | EC | 84 | 72 | 96 | 115 | 143 | 500 | 336 |

| EC-708-6 | EC | 84 | 96 | 72 | 115 | 167 | 500 | 336 |

| EC-708-7 | EC | 84 | 96 | 84 | 115 | 167 | 500 | 392 |

| DSUS-12-462-5 | EC | 48 | 72 | 28 | 95.5 | 105.7 | 1250 | 56 |

| EC-708-8 | EC | 84 | 96 | 96 | 115 | 167 | 500 | 448 |

| EC-710-6 | EC | 84 | 120 | 72 | 118 | 191 | 500 | 420 |